Scope

- Install the highest performing furnace that project funding will allow, meeting the heating load of the project.

- Highest performance combustion furnaces are sealed-combustion, direct-vent, condensing gas furnaces, with an AFUE exceeding 94%. These furnaces draw combustion air from and release combustion byproducts outdoors.

- Install in accordance with manufacturers’ instructions and relevant standards, including:

- ACCA Standard 5: HVAC Quality Installation Specification

- ACCA Technician’s Guide for Quality Installations

- ACCA Standard 9: HVAC Quality Installation Verification Protocols.

- Properly size the furnace and blower based on:

- ACCA Manual J heating and cooling load calculations

- ACCA Manual S sizing guidelines.

- Design an efficient air distribution system with a compact layout per ACCA Manual D.

- Consider alternative heating equipment if the design load is lower than the selected furnace’s lowest output rating.

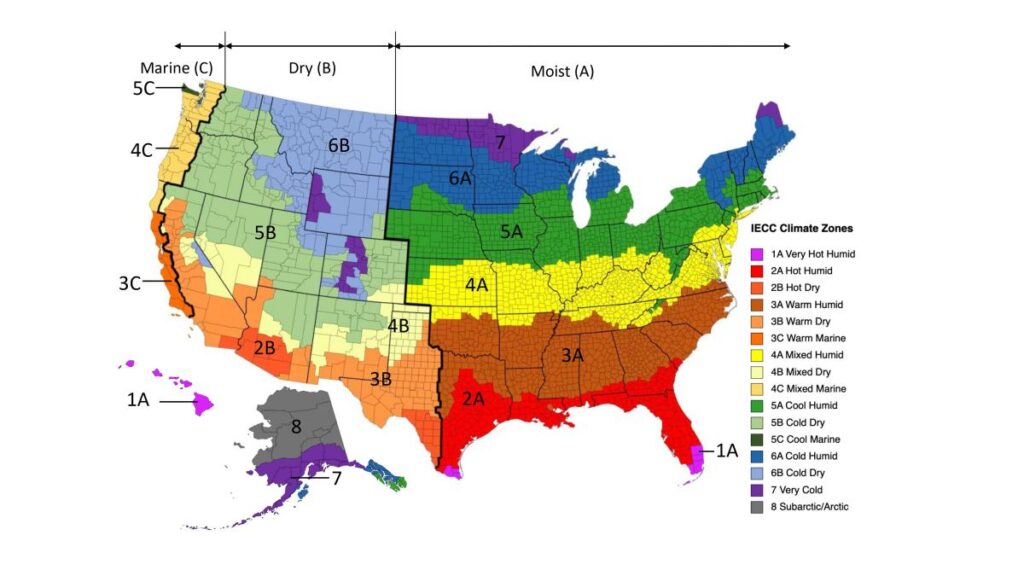

- For energy-efficiency programs like ENERGY STAR or DOE Zero Energy Ready Homes, select a compliant furnace based on climate zone (refer to Compliance tab) using the International Energy Conservation Code (IECC) climate zone map.

Description

- Forced air furnaces are common in the USA, primarily fueled by natural gas.

- Propane and fuel oil used in areas without natural gas availability; oil furnaces have slightly lower efficiencies than gas.

- Electric furnaces are less common due to efficiency concerns.

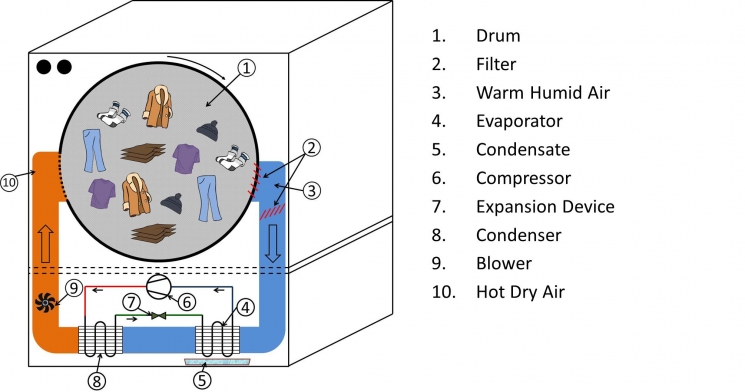

- Some furnaces incorporate indoor refrigerant cooling coils for cooling.

- Hybrid systems combine gas furnaces with heat pumps for heating and cooling.

- Ducted and ductless heat pumps offer an alternative to combustion furnaces.

- Furnaces are classified in the International Mechanical Code and National Fuel Gas Code.

International Mechanical Code (IMC) Classification (2009 and 2012)

- Direct-vent: Derives air for combustion from outdoors and vents flue gases outside.

- Mechanical draft: Removes flue gases mechanically through induced or forced draft.

- Natural draft: Removes flue gases naturally without mechanical assistance.

National Fuel Gas Code (NFPA 54) Classification (2012)

- Category I: Negative pressure flue, burner draws air from combustion appliance zone (CAZ).

- Older Category I furnaces have open draft hoods, lower efficiency.

- Newer Category I furnaces use induced draft fans, higher efficiency.

Category I Furnaces with Induced Draft Fans

- Mechanically drafted, but potential for backdrafting.

- Combustion safety test needed.

- Don’t use CAZ as return air plenum.

Category III Furnaces

- Positive pressure flue, non-condensing.

- High-efficiency oil furnaces.

- Draw combustion air from outside.

- Vent exhaust gases outside.

Category IV Furnaces

- Positive pressure flue, flue gases under 140°F.

- Achieve >90% AFUE.

- Sealed-combustion, direct vent.

- Draw combustion air from outside.

- PVC vent pipes.

How to Select and Install a Furnace

- Choose highest-performing furnace within budget.

- Follow manufacturers’ instructions and standards.

- Proper sizing based on load calculations.

- Efficient air distribution system design.

- Install per manufacturer’s instructions.

- Direct-vent installation preferred.

- Combustion safety test for Category I furnaces.

- Proper condensate drainage for condensing furnaces.

Ensuring Success

- Choose Category IV high-efficiency, sealed-combustion, direct vent system furnace whenever possible.

- Follow manufacturers’ instructions and standards.

- Proper sizing and duct design.

- Combustion safety test for Category I furnaces.

- Proper condensate drainage for condensing furnaces.

Climate Considerations

ENERGY STAR and DOE Zero Energy Ready Homes have climate-specific criteria for furnace selection based on AFUE and climate zones.

- Warm Climates:

- Size furnaces for cooling load.

- Stay within ACCA Manual S oversizing limits.

- Consider alternative heating and cooling options like heat pumps.

- Cold Climates:

- Use sealed-combustion, direct-vent, or power-vented equipment.

- Ensure air intake and exhaust discharge vents are snow-resistant.

- Direct condensate lines to indoor drains.

Compliance with Codes and Standards

Compliance in the ENERGY STAR Single-Family New Homes, Version 3/3.1 (Rev. 11)

- The ENERGY STAR Reference Design Home is crucial in determining the ENERGY STAR ERI (Energy Rating Index) Target for certified homes.

- While the features in the Reference Design Home are not mandatory, they play a significant role in achieving the ERI Target.

- Mandatory Requirements for All Certified Homes, Exhibit 2, include specifications for duct leakage limits, insulation levels, and fenestration performance.

- EPA recommends reviewing Exhibit 2 before selecting measures as it contains important requirements.

DOE Zero Energy Ready Home (Revision 07)

- Builders can choose between a prescriptive or performance path in the DOE Zero Energy Ready Home program.

- The prescriptive path requires meeting or exceeding minimum HVAC efficiencies listed in Exhibit 2 of National Program Requirements (Rev 07).

- The performance path allows customization but must achieve a minimum HERS (Home Energy Rating System) index equivalent to Exhibit 2 requirements.

International Energy Conservation Code (IECC)

- Various versions of IECC specify requirements for heating and cooling systems.

- These include the need for programmable thermostats, duct insulation, duct tightness verification, and equipment sizing in accordance with ACCA Manual S and J.

- 2009 IECC

- 403.1: Each heating and cooling system should have its own thermostat. If the primary heating system is a forced-air furnace, at least one thermostat must be programmable.

- 403.2: Ducts – Insulate supply ducts in attics to at least R-8 and all other ducts to at least R-6. Duct tightness verification is required.

- 403.6: Heating equipment sizing shall be in accordance with Section M1401.2 of the International Residential Code.

- 2012 IECC

- 403.1: Similar to 2009 IECC, heating and cooling systems must have their own thermostats. Programmable thermostats are required for forced-air furnaces.

- 403.2: Duct insulation requirements remain the same, with added verification of air handler air leakage.

- 403.6: Heating equipment sizing should follow ACCA Manual S and J.

- 2015, 2018, and 2021 IECC

- 403.1: Continues the requirement for separate thermostats and programmable thermostats for forced-air furnaces.

- 403.3.1: Insulation requirements for supply and return ducts in attics.

- 403.7: Heating equipment sizing should adhere to ACCA Manual S and J.

- Retrofit (Applies to 2009, 2012, 2015, 2018, and 2021 IECC)

- Section R101.4.3: Addresses additions, alterations, renovations, or repairs, ensuring compliance without affecting unaltered portions of existing buildings.

- Chapter 5: Controls alteration, repair, addition, and change of occupancy of existing buildings and structures.

International Residential Code (IRC)

- IRC covers general requirements, installation, clearances, and location for heating and cooling equipment.

- It also addresses condensate disposal and provides guidelines for additions, alterations, renovations, and repairs in existing buildings.

- Chapter 14: Heating and Cooling Equipment – General requirements, installation, clearances, and location.

- Chapter 24: Fuel Gas – Extracted from the International Fuel Gas Code with modifications, covering gas piping systems, appliances, venting systems, and combustion air configurations.

- Section M1441.3: Addresses the disposal of condensate from cooling coils and evaporators to an approved location.

- Retrofit (Applies to 2009, 2012, 2015, 2018, and 2021 IRC)

- Section R102.7.1: Ensures that additions, alterations, renovations, or repairs conform to code provisions without affecting unaltered portions of existing buildings.

- Appendix J: Regulates the repair, renovation, alteration, and reconstruction of existing buildings to encourage their continued safe use.

International Mechanical Code (IMC)

- Compliance with relevant sections of IMC is essential for HVAC systems.

- IMC includes definitions for combustion appliances based on venting type in Chapter 2.

Air Conditioning Contractors of America (ACCA) Standards

ACCA Manual S – Residential Equipment Selection, ANSI/ACCA 3-Manual S-2004

- Provides guidance on selecting and sizing heating and cooling equipment based on local climate and ambient conditions at the building site.

- Covers sizing strategies for various types of cooling and heating equipment.

- Includes comprehensive manufacturers’ performance data on sensible, latent, or heating capacity for different operating conditions.

ACCA Manual D – Residential Duct Systems, ANSI/ACCA 1-Manual D-2011

- Offers ANSI-recognized principles and calculations for duct sizing applicable to all duct materials.

- Addresses system operating point, airway sizing for single-speed and multi-speed (ECM) blowers, and the impact of duct friction and fitting pressure drop on blower performance.

- Provides equivalent length data for duct systems.

ACCA Manual J – Residential Load Calculation, ANSI/ACCA 2-Manual J-2011

- Provides guidance for calculating heating and cooling loads, essential for equipment sizing.

- Applicable to single-family detached homes, small multi-unit structures, condominiums, townhouses, and manufactured homes.

ACCA Standard 5: HVAC Quality Installation Specification, ANSI/ACCA 5 QI-2010

- Specifies nationally recognized criteria for the proper installation of residential and commercial HVAC systems.

- Covers aspects of design, installation, distribution systems, and documentation.

- Ensures quality installation of forced air furnaces, boilers, air conditioners, and heat pumps.

- The Technician’s Guide for Quality Installation explains the HVAC Quality Installation (QI) Specification and provides detailed procedures for compliance.

ACCA Standard 9: HVAC Quality Installation Verification Protocols, ANSI/ACCA 9 QIVP-2009

- Specifies protocols for verifying the installation of HVAC systems in accordance with ACCA Standard 5.

- Provides guidance for contractors, verifiers, and administrators participating in verification efforts.

- Ensures that HVAC installations meet the requirements set out in Standard 5.

Residential Energy Services Network (RESNET) Mortgage Industry National Home Energy Rating Systems Standards

- Establishes procedures and technical standards for conducting home energy ratings, including home energy audits.

- Ensures consistency and accuracy in assessing the energy efficiency of residential properties.

- Important for evaluating and improving the energy performance of homes in the mortgage industry.

National Fuel Gas Code (NFPA-54 2015):

- NFPA-54 specifies venting requirements for gas-fired furnaces, considering flue gas temperatures and materials used for vent pipes.

- Detailed requirements for venting systems are outlined in ANSI Z223.1, the National Fuel Gas Code.

Ensure that these compliance guidelines are followed meticulously to achieve energy efficiency and meet certification requirements in residential construction. For exact code language, refer to the applicable codes, which may require purchase from the publisher.

How to Retrofit Combustion Furnaces

Scope:

- Assess the Need for Replacing or Upgrading the HVAC System: The scope involves evaluating whether it’s necessary to replace or upgrade the existing HVAC system.

- Review the Pre-Retrofit Assessment of Combustion Appliances: Ensure that safe conditions exist and that unsafe conditions won’t be introduced when upgrading or replacing combustion appliances or making other energy-efficiency upgrades in a home with combustion appliances.

- Reference to U.S. Department of Energy’s Standard Work Specifications: For more information regarding combustion furnaces.

Description:

Assessment:

- HVAC equipment typically has a lifespan of 15 to 20 years. New equipment offers higher efficiencies, safety, control flexibility, and performance capabilities. Assess existing equipment to determine if repairs, upgrades, or expansion are necessary. Consider factors like performance and reliability alongside efficiency.

- Resources:

- Pre-Retrofit Assessment of Existing HVAC Systems

- Existing HVAC System Upgrade or Expansion

- Building America Best Practices Series Volume 14 – HVAC: A Guide for Contractors to Share with Homeowners

Replacement:

- Replacing HVAC equipment can be costly but often results in significant energy cost savings and improved comfort. Estimate energy cost savings based on utility bills, replacement equipment cost, and efficiency improvements.

- Resources for different HVAC systems:

- Gas-Fired Boilers

- Oil-Fired Boilers

- Condensing Boilers

- Traditional Split Heat Pumps

- Mini-Split (Ductless) Heat Pumps

- Geothermal Heat Pumps

Repair/Upgrade:

- Regular maintenance and proper commissioning of HVAC equipment can improve performance significantly. The Air Conditioning Contractors of America Association, Inc. (ACCA) provides guidance on design, sizing, installation, commissioning, and maintenance of HVAC equipment.

- ACCA Standards include:

- ACCA Standard 5 (2015): HVAC Quality Installation Specification

- ACCA Standard 12 (2014): Home Evaluation & Performance Improvement

- ACCA Standard 9 (2016): HVAC Quality Installation Verification Protocols

- ACCA Standard 4 (2013): Maintenance of Residential HVAC Systems

- ACCA Standard 6 (2015): Restoring the Cleanliness of HVAC Systems

- Ductwork inspection and sealing may be necessary to improve performance. Leak, uninsulated, constricted, or disconnected ducts can negatively impact heating and cooling systems.

Additions:

- When adding rooms or converting spaces in a home, consider if the existing HVAC system can handle the additional load. Perform load calculations (ACCA Manual J) to determine if the current system is sufficient.

- If necessary, add a new HVAC system or replace the existing one for efficiency or capacity reasons. Properly size new ducts according to ACCA Manual D.

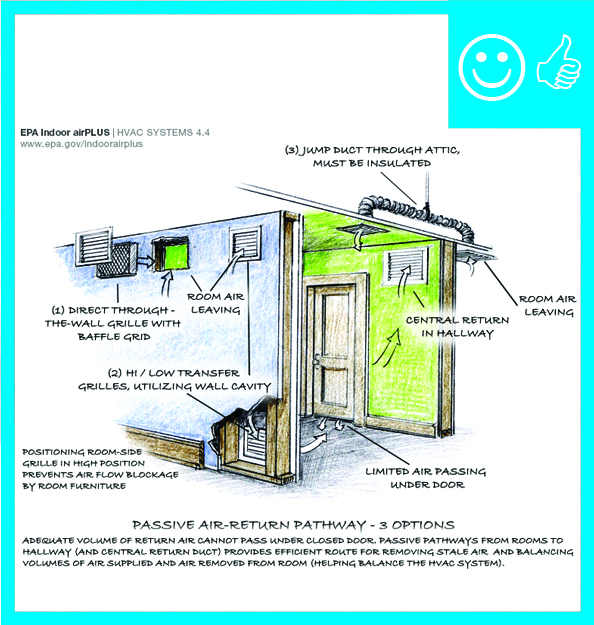

- Ensure proper air flow to the addition and maintain air flow balance in the existing house by using dedicated supply trunks, manual balancing dampers, and transfer grilles.

Success:

- Some older gas or oil furnaces and boilers may have asbestos jacketing or insulation. For remediation information, refer to the EPA’s website.

This comprehensive guide covers combustion furnace installation and types while referencing building code chapters and numbers.

For more detailed guidance and resources, refer to the U.S. Department of Energy’s Standard Work Specifications and relevant industry standards and directories.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.