Introduction: APA’s “Moisture Movement and Water Vapor Permeance of Wood Structural Panels and Wood Wall Construction, Form J450” offers critical insights into moisture dynamics in construction, essential for the structural integrity and longevity of buildings. This concise summary highlights the most significant points, with specific references to standards and measurements.

Key Insights:

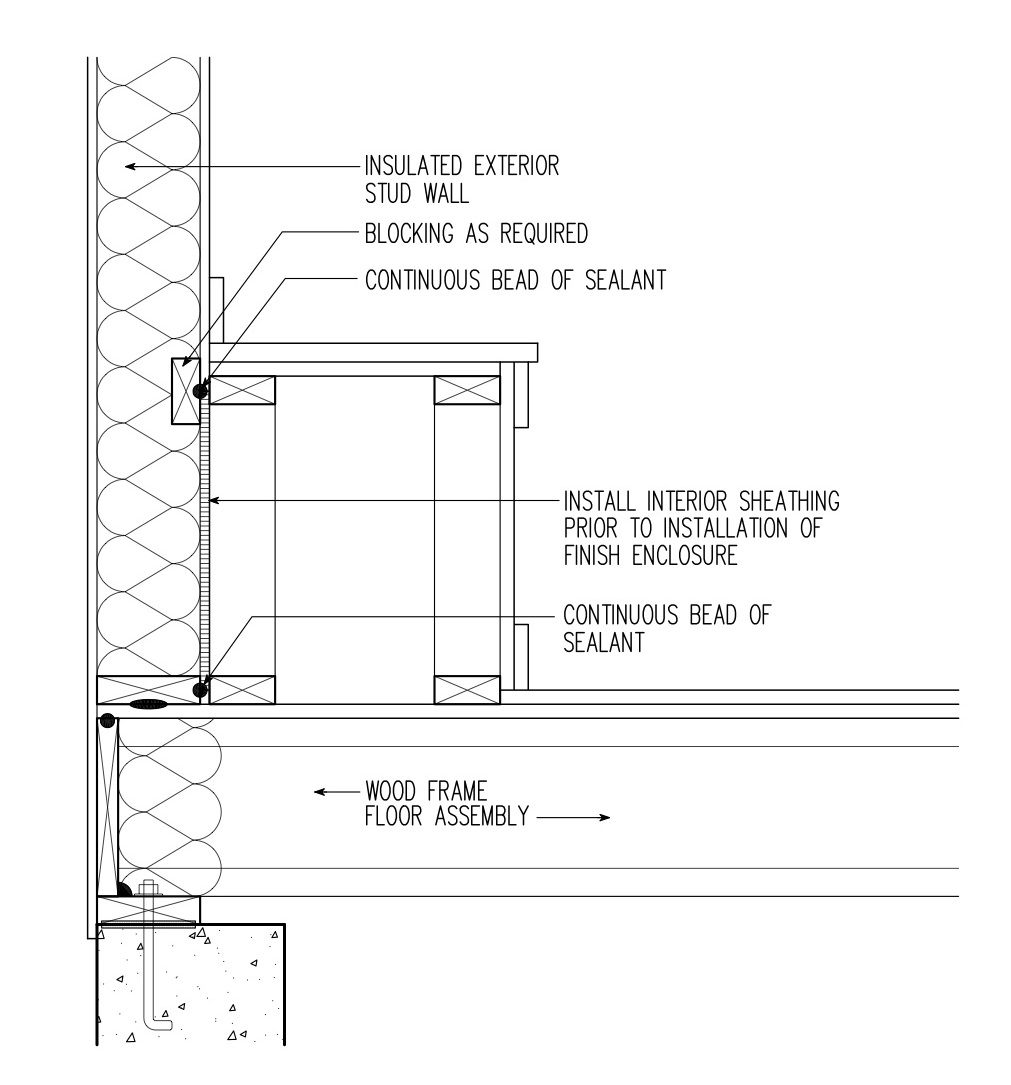

- Moisture Control in Buildings: Proper system design, installation, and maintenance are key to managing moisture, focusing on preventing leaks and condensation.

- Wood’s Moisture Dynamics: Wood’s moisture content fluctuates with environmental conditions, affecting its performance in building structures.

- Vapor Movement and Permeance: Water vapor movement through materials is a crucial aspect of wall design to prevent condensation issues. Water vapor permeance is measured using ASTM Method E 96, reported in perms (grains per hour per ft² per inch of mercury vapor pressure).

Specific Standards and Measurements:

- ASTM E 96: Standard test method for water vapor permeance.

- IBC® and IRC® Classifications: Class I vapor retarders (0.1 perm or less), Class II (greater than 0.1 up to 1.0 perms), and Class III (greater than 1.0 up to 10 perms).

- 2006 IBC and IRC: Classify materials with a permeance of 5 perms or more as vapor permeable.

- Section R318.1 of the 2006 IRC and Section 502.5 of the 2006 IECC: Require an approved vapor retarder of 1.0 perms or less on the warm-in-winter side of the wall in most climates.

- Permeance Measurements: At 50% humidity, the vapor permeance of 7/16-inch OSB sheathing is approximately 2 perms, increasing to 12 perms at 85% humidity.

Practical Application:

- Selecting appropriate vapor retarders is critical in minimizing moisture problems.

- Wood panels like plywood and OSB act as adaptive vapor retarders, changing permeability with relative humidity.

- Avoid double vapor retarders (impermeable barriers on both sides of a wall) to prevent moisture trapping.

Considerations for Exterior Wall Sheathing Material:

- Bulk Water Intrusion: Flashings should be detailed around doors, windows, roofs, walls, and chimneys to prevent water intrusion.

- Vapor Permeance Ratings: Consider these ratings for sheathing products to minimize moisture issues.

- Permeability of Sheathing Products: Example – a rigid foam sheathing tested by APA has a permeance range of 0.5 to 1.2 perms. Avoid double vapor retarders, i.e., impermeable barriers on both interior and exterior walls.

- Wood Panels as Smart Vapor Retarders: Wood panels like plywood and OSB adapt their permeability with humidity changes, aiding moisture diffusion through walls (sub-note d).

- Encouraging Drying Mechanisms: Design wall systems to promote drying, and refer to local building codes for requirements.

Conclusion: For resilient and safe building designs, understanding moisture movement and vapor permeance is fundamental.

For more personalized guidance, consult with engineers and local building codes specific to your location. For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field

![How Much Does a New Roof Cost in Illinois? [2024 Pricing Guide]](https://www.news.alliedemergencyservices.com/wp-content/uploads/2024/05/DALL·E-2024-05-07-15.14.25-A-professional-roofing-contractor-inspecting-a-roof-in-the-foreground-of-a-picturesque-suburban-neighborhood-in-Illinois.-The-contractor-is-wearing-a--150x150.webp)