When it comes to constructing homes that prioritize energy efficiency, comfort, and durability, innovation is key. One such innovation making waves in the construction industry is the utilization of double-wall architectural features. This advanced construction technique not only enhances the aesthetic appeal of homes but also serves as a formidable defense against energy loss and external elements.

Technical Marvel: Understanding Double-Wall Construction

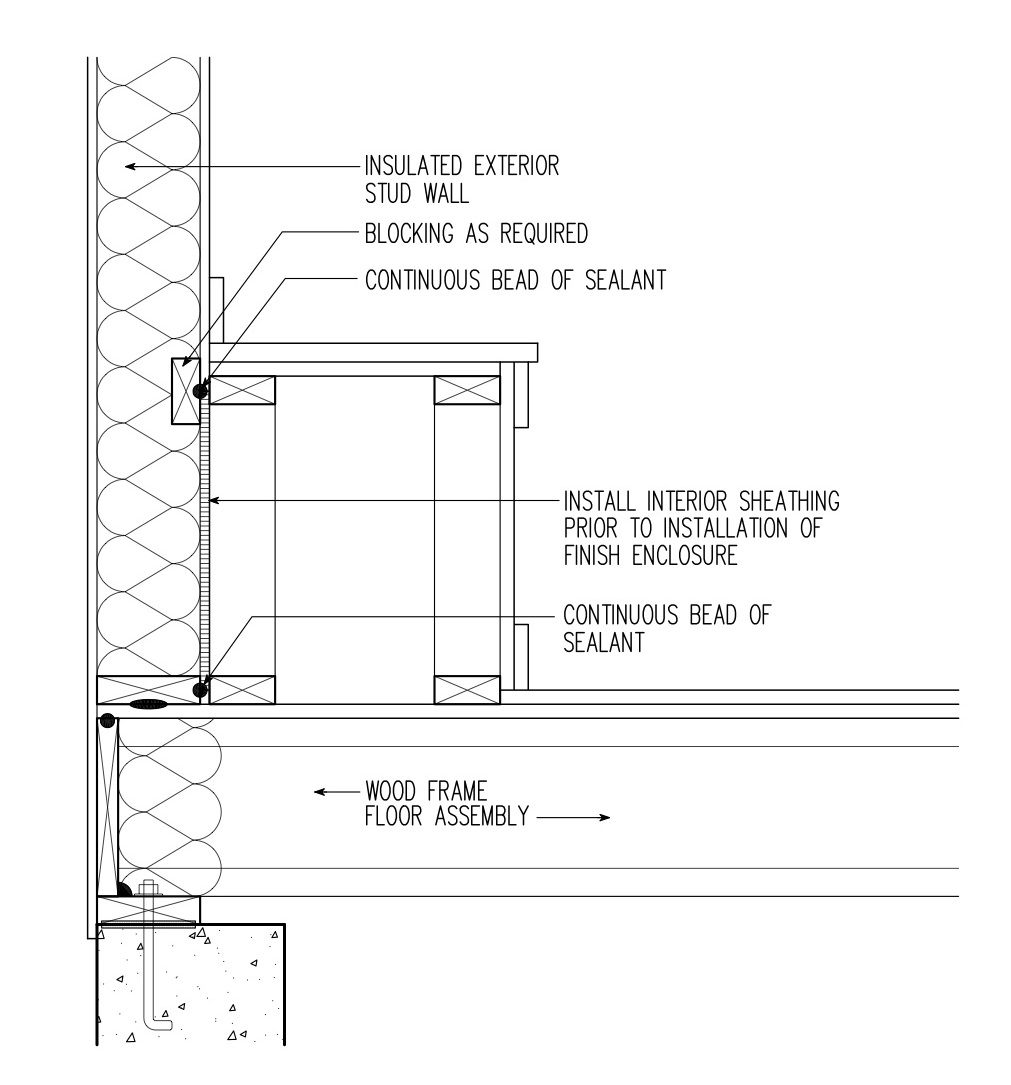

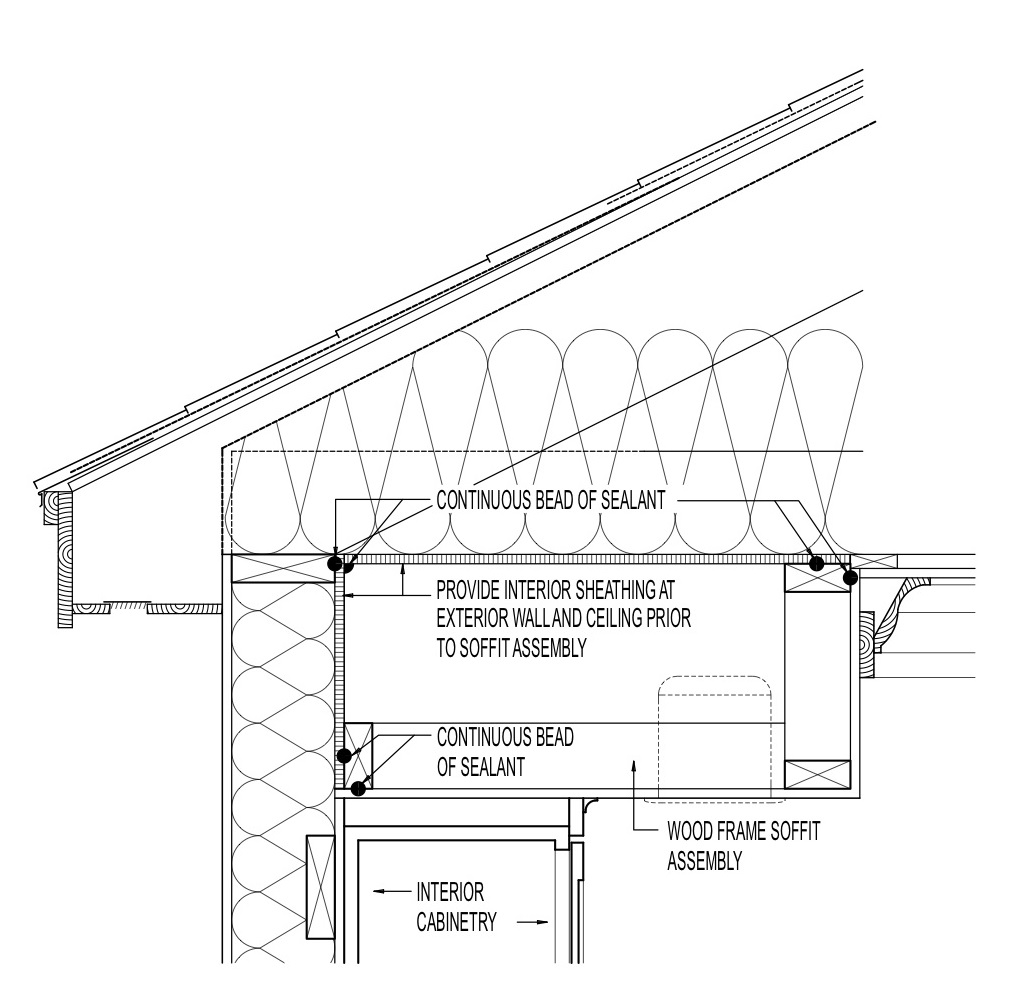

At the heart of double-wall architectural features lies a simple yet ingenious concept – the incorporation of two stud walls separated by an air space. This design allows for the creation of a deep wall cavity, typically around 10 inches deep when utilizing two 2×4 framed walls spaced three inches apart. This spacing effectively eliminates thermal bridging, resulting in a highly insulated structure akin to a thermal blanket for your home.

Benefits Beyond Measure

The advantages of double-wall construction extend far beyond mere insulation. By incorporating this technique into your home design, you’re not just building a house; you’re investing in lasting comfort and efficiency. Here’s why:

- Enhanced Insulation: The double-wall thermal blanket offers superior insulation, significantly reducing heat loss and gain through structural framing. This translates to lower energy bills and a more comfortable indoor environment year-round.

- Whisper-Quiet Living Spaces: Say goodbye to unwanted noise intrusion. The thick, insulated walls of double-wall construction create a barrier against external noise, ensuring peace and tranquility within your home.

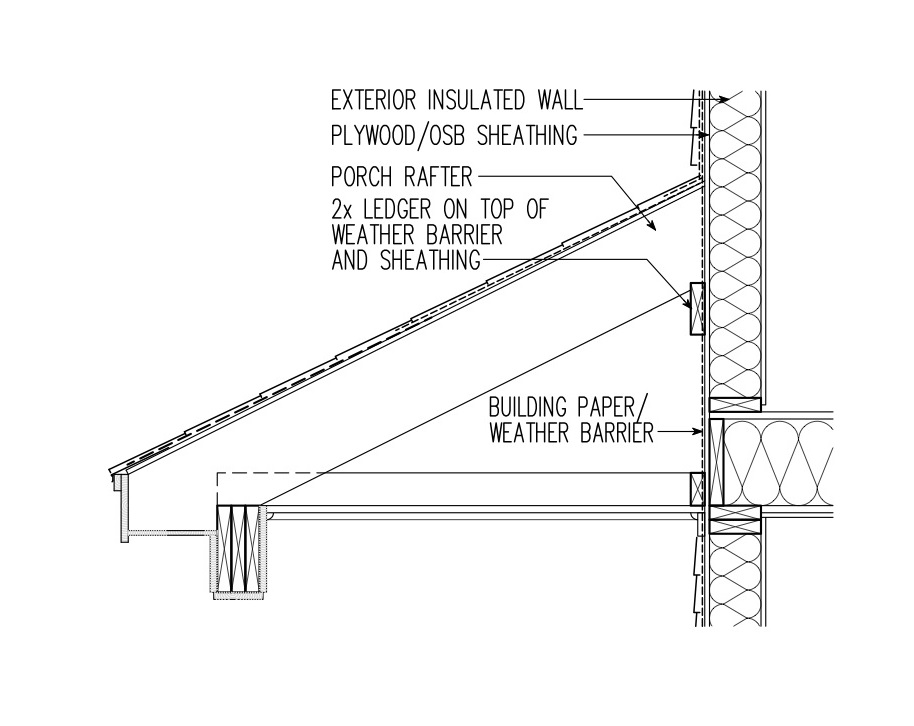

- Durable and Weather-Resistant: From harsh winters to scorching summers, your home deserves protection against the elements. Double-wall architectural features provide added resilience against weather extremes, safeguarding your investment for years to come.

HOW TO AIR SEAL AND INSULATE A DOUBLE WALL USING BLOWN-IN INSULATION

- Frame the Exterior Wall: Utilize the same stud framing as the rest of the exterior wall, preferably 2×6, 24-inch on-center. Refer to Minimum Wall Studs guidelines. Sheathe with identical exterior sheathing as used on other exterior walls.

- Install Second Framing Section: Inside the exterior wall framing, where a thicker wall is desired, install a second section of framing using 2×4 or 2×6, 24-inch on-center framing.

- Blown-in Insulation Application:

- Tack netting to the interior face of the interior wall studs.

- Blow in loose fiberglass or cellulose insulation when other walls are being insulated.

- Ensure thorough filling of the wall cavity to the proper density to minimize settling.

- Drywall Installation:

- When other walls are drywalled, proceed with drywalling the double wall.

- Caulk the drywall to the framing at the top plate, bottom plate, and studs.

- Mud and tape seams and corners to ensure a seamless finish.

- Air Barrier Establishment: The interior drywall and exterior sheathing function as the interior and exterior air barriers, respectively. Ensure proper sealing to maintain air-tightness and insulation efficiency.

HOW TO AIR SEAL AND INSULATE A DOUBLE WALL USING BATT INSULATION

- Frame the Exterior Wall: Use the same stud framing as the rest of the exterior wall, preferably 2×6, 24-inch on-center. Refer to Minimum Wall Studs guidelines. Sheathe with identical sheathing as used on other exterior walls.

- Install Air Barrier: Over the studs on the section of wall to be double framed, apply an air barrier. This can be drywall, OSB, plywood, or rigid foam. Avoid using polyethylene or any other Class 1 vapor barrier material.

- Caulking: Along the interior facing side of the air barrier, caulk at all four edges to ensure a tight seal.

- Second Wall Framing Installation:

- Install the second wall framing using 2×4 or 2×6, 24-inch on-center framing.

- Press the second framing members against the caulk to seal the framing to the air barrier along all four sides.

- Insulation Application:

- Fill the interior wall cavity with batt insulation to meet the required R-value for exterior walls in your climate zone.

- Drywall Installation:

- Once the insulation is in place, proceed with drywalling the double wall.

- Caulk the drywall to the framing at the top plate, bottom plate, and studs to maintain air-tightness.

- Mud and tape seams and corners for a smooth finish.

- Air Barrier Establishment: The interior drywall and exterior sheathing serve as the interior and exterior air barriers, respectively. Ensure proper sealing to prevent air leakage and optimize insulation efficiency.

HOW TO AIR SEAL AND INSULATE A DOUBLE WALL USING SPRAY FOAM INSULATION

- Frame the Exterior Wall: Utilize the same stud framing as the rest of the exterior wall, preferably 2×6, 24-inch on-center (refer to Minimum Wall Studs). Sheathe with identical sheathing as used on other exterior walls.

- Install Second Wall Framing: Using 2×4 or 2×6, 24-inch on-center framing, install the second wall framing.

- Fill with Spray Foam Insulation:

- Fill the double-stud wall cavity with the desired depth of spray foam along the inside surface of the exterior sheathing.

- Drywall Installation:

- Proceed with drywalling the double wall after completing insulation.

- The foam does not need to touch the interior drywall since it serves as its own air barrier.

- Ensure proper drywall installation when the rest of the walls are drywalled.

- Establishment of Air Barrier:

- The foam serves as its own air barrier, eliminating the need for additional sealing.

- The exterior sheathing functions as the exterior air barrier, ensuring air-tightness and insulation efficiency.

Invest in Your Comfort and Savings

At Allied Emergency Services, we understand the importance of quality construction and lasting value. That’s why we’re proud to offer double-wall architectural features as part of our comprehensive range of services. By choosing double-wall construction, you’re not just building a house; you’re investing in your family’s comfort, well-being, and financial savings.

Bringing Double-Wall Benefits to Your Home

Our expert team specializes in the installation and maintenance of double-wall architectural features. Whether you’re looking to incorporate half-height or full-height walls as a striking architectural element, we’ve got you covered. Our meticulous approach ensures that every aspect of the double-wall construction, from air sealing to insulation, is executed to perfection.

Compliance with Building Codes and Programs

- ENERGY STAR Single-Family New Homes, Version 3/3.1 (Rev. 11):

- 2. Fully-Aligned Air Barriers: At each insulated location, ensure a complete air barrier is provided, fully aligned as follows:

- Walls: At exterior vertical surface of wall insulation in all climate zones; also at interior vertical surface of wall insulation in Climate Zones 4-8.

- 2.5 Double-walls and all other exterior walls.

- 2. Fully-Aligned Air Barriers: At each insulated location, ensure a complete air barrier is provided, fully aligned as follows:

- DOE Zero Energy Ready Home (Revision 07):

- Exhibit 1 Mandatory Requirements:

- Certified under the ENERGY STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Program.

- Ceiling, wall, floor, and slab insulation shall meet or exceed 2015 IECC levels and achieve Grade 1 installation.

- Exhibit 2 DOE Zero Energy Ready Home Target Home:

- Whole house leakage must be tested and meet specified infiltration limits based on climate zones.

- Exhibit 1 Mandatory Requirements:

- 2009-2021 IECC and IRC Insulation Requirements Table: Refer to the table for minimum insulation requirements for ceilings, walls, floors, and foundations in new homes.

- 2009 International Energy Conservation Code (IECC):

- Table 402.4.2 Air Barrier and Insulation Inspection Component Criteria: Ensure proper installation of air barriers and insulation to prevent air leakage.

- 2012 IRC:

- Table N1102.4.2 Air Barrier and Insulation Inspection Component Criteria: Similar to IECC, ensure proper installation of air barriers and insulation.

- American Society for Testing Materials (ASTM) E1677-11: Standard specification for air barrier material/system for low-rise framed building walls, covering minimum performances and criteria for air barriers in framed buildings.

How We Ensure Success: Quality Every Step of the Way

When you choose Allied Emergency Services, you’re choosing a partner committed to excellence. Our rigorous quality control measures ensure that every double-wall construction project meets the highest standards of performance and durability. From initial planning to final inspection, we’re with you every step of the way.

Experience the Allied Difference

Discover the difference that double-wall architectural features can make in your home. Contact Allied Emergency Services today to learn more about our innovative construction solutions and schedule a consultation with our team of experts.

Ensure compliance with these requirements to meet the standards for ENERGY STAR and DOE Zero Energy Ready Home certifications, promoting energy efficiency and sustainability in residential construction.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.