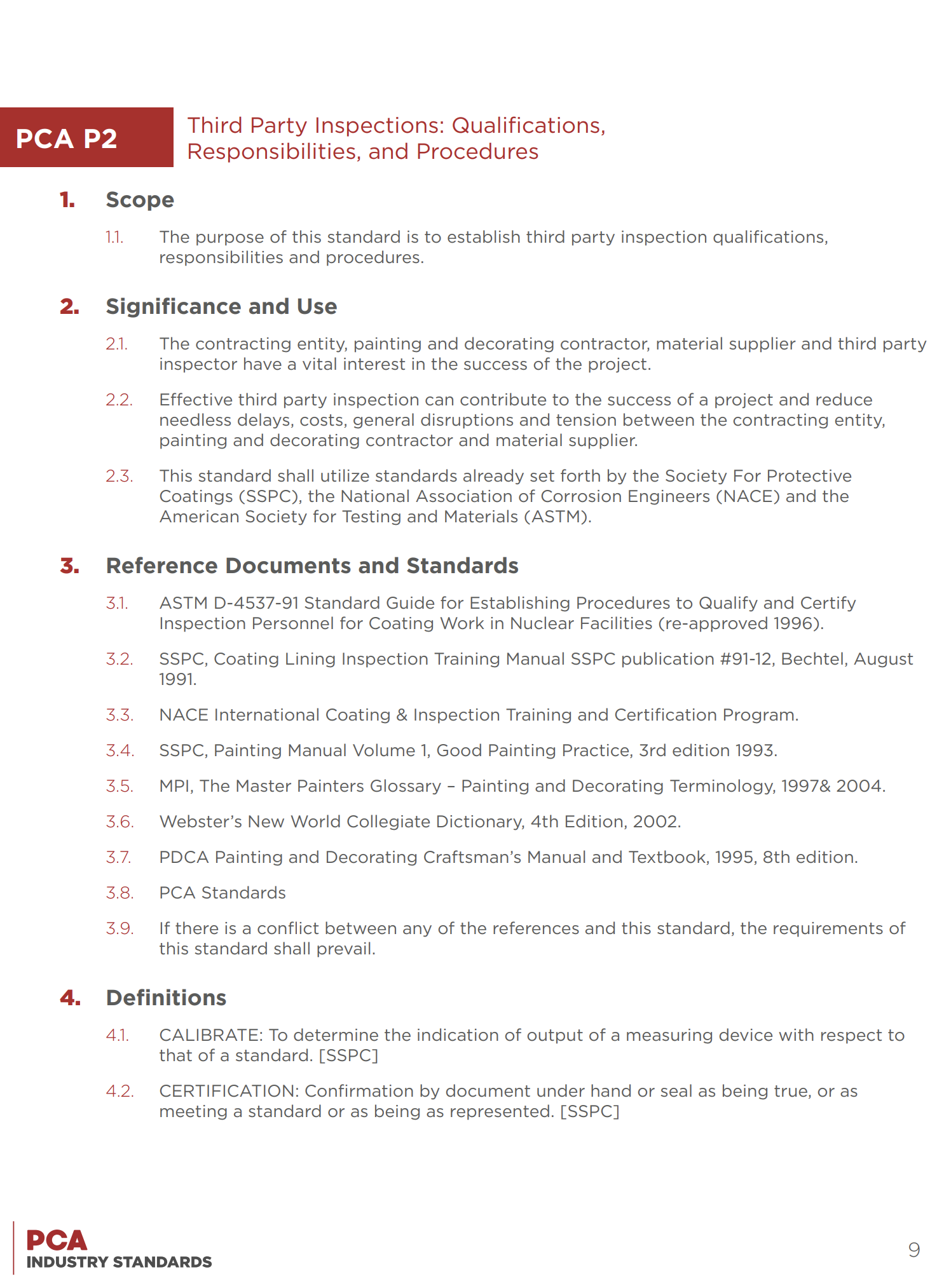

Introduction

Third-party inspections are an integral part of any restoration project. They ensure that the work meets the expected standards, reducing the chances of disputes, delays, and additional costs. The Painting and Decorating Contractors of America (PCA) has set forth a series of standards to govern this critical phase. Today, we will delve into PCA Standard P2, which focuses on Third-Party Inspections—its qualifications, responsibilities, and procedures.

Scope and Significance

PCA Standard P2 establishes the qualifications, responsibilities, and procedures for third-party inspections in painting and decorating projects. The standard serves as a guide for contracting entities, material suppliers, and painting and decorating contractors, aiming to reduce project delays, costs, and misunderstandings. The standard also incorporates guidelines from the Society For Protective Coatings (SSPC), the National Association of Corrosion Engineers (NACE), and the American Society for Testing and Materials (ASTM).

Key Definitions

- Calibrate: To determine the output of a measuring device against a standard.

- Certification: Official confirmation that a particular standard has been met.

- Defective: Subpar in relation to written specifications.

- Inspector: A qualified person who examines and documents work to ensure it meets accepted trade practices, standards, and specifications.

- Quality Assurance (QA): Verification that materials and methods conform to the specification to achieve a desired result.

- Third Party: An independent entity not directly involved in the contract but responsible for the coatings application work.

Inspection Personnel Requirements

- Education, Training, and Experience: Inspectors should have completed a recognized education and training program, and have at least three years of relevant experience in the painting industry.

- Physical Qualifications: Annual eye examinations and color perception tests are recommended.

- Functional Qualifications: Inspectors should have a current working knowledge of inspection equipment required for the project.

Job Coordination and Pre-Job Conference

A pre-job conference is crucial and should include the contracting entity, material supplier, and painting and decorating contractor. Key topics include:

- Scope of work

- Specification requirements

- Material Safety Data Sheets (MSDS)

- Work schedule

- Inspector qualifications

- Testing procedures

- Resolution of disputes

Inspection Hold Points & Documentation

- Hold Points: Points in the work sequence where inspections should be carried out.

- Non-compliant Conditions: Should be reported immediately in writing to the painting and decorating contractor and the contracting entity.

Reference Documents and Standards

Understanding PCA Standard P2 is facilitated by several other documents that serve as critical references. These documents provide foundational knowledge, industry standards, and terminology essential to grasp the full scope and implications of PCA P2. Below are the key references:

Coating Work and Inspection Standards

- ASTM D-4537-91: A comprehensive guide for establishing procedures to qualify and certify inspection personnel for coating work in specialized facilities like nuclear plants.

- SSPC Coating Lining Inspection Training Manual (SSPC publication #91-12): A manual that offers detailed training guidelines for coating and lining inspection, published by Bechtel in August 1991.

- NACE International Coating & Inspection Training and Certification Program: A program that provides certification and training for coating inspection.

Painting and Decorating Guidelines

- SSPC, Painting Manual Volume 1, Good Painting Practice, 3rd edition 1993: A manual that sets forth best practices for painting.

- MPI, The Master Painters Glossary – Painting and Decorating Terminology, 1997 & 2004: A glossary that defines terms and terminologies in painting and decorating.

- PDCA Painting and Decorating Craftsman’s Manual and Textbook, 1995, 8th edition: A manual and textbook that covers various aspects of painting and decorating in depth.

General and Legal References

- Webster’s New World Collegiate Dictionary, 4th Edition, 2002: For any terminological clarifications.

- PCA Standards: Various PCA standards that define and guide the painting and decorating industry.

- If there is a conflict between any of the references and PCA Standard P2, the requirements of this standard shall prevail: An important note highlighting the overriding authority of PCA P2 when conflicts in guidelines or definitions arise.

Conclusion

Understanding PCA Standard P2 can significantly improve project outcomes by clarifying roles and responsibilities. This can ultimately lead to fewer misunderstandings, delays, and additional costs, making the standard an invaluable resource for anyone involved in painting and decorating projects, including those in the insurance restoration industry.

Contact Details

For more information on how PCA standards apply to your restoration project, consult with painters and local building codes specific to your location. For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the fiel