Security measures for vacant or abandoned buildings are essential to prevent unauthorized access and protect the property from damage. Allied Emergency Services, INC follows comprehensive boarding-up procedures to ensure the security of structures. Below are detailed bullet points outlining the security measures, materials used, and installation procedures.

Security Measures

- Barricading Openings

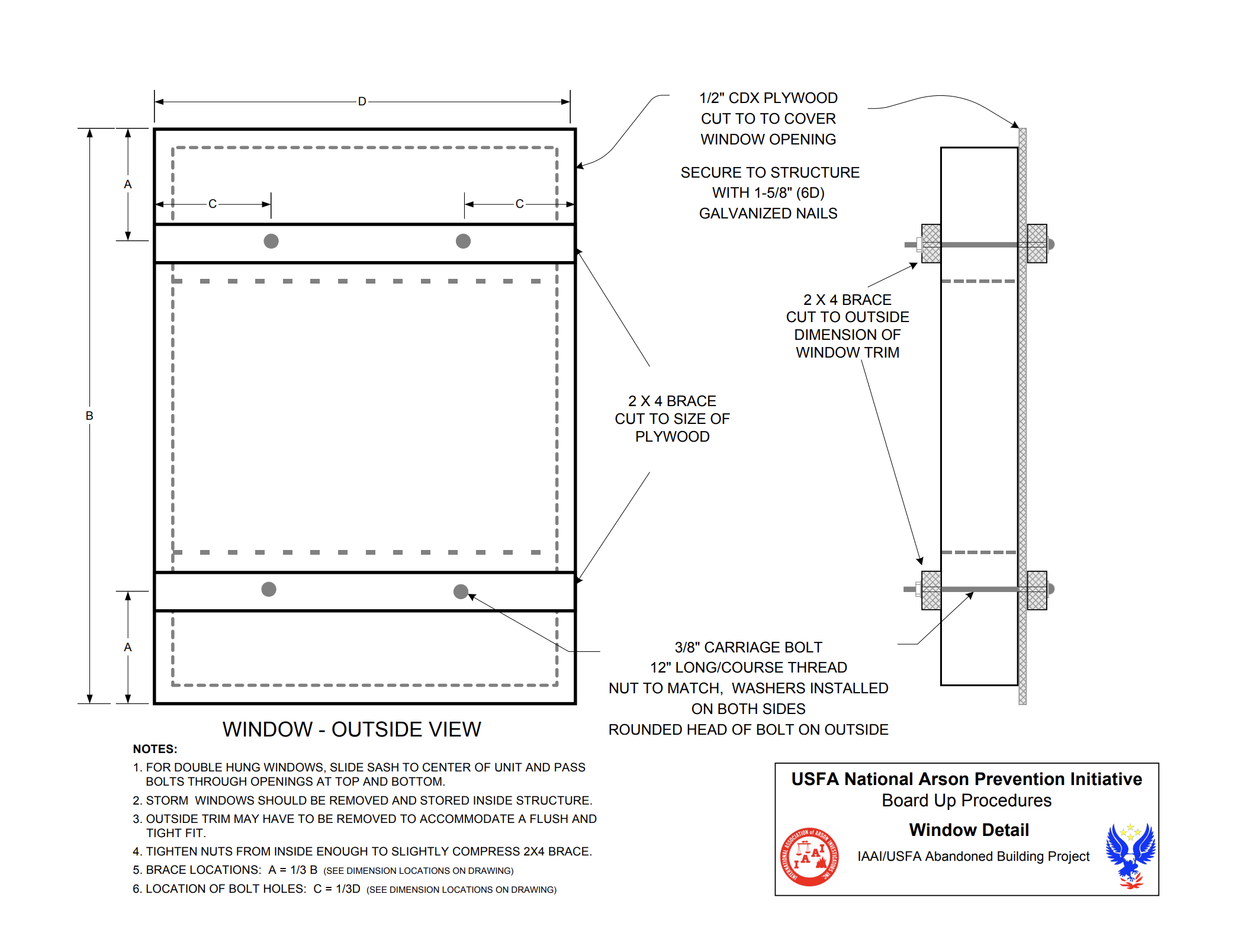

- All openings in the basement, first-floor doors and windows, and any entry point accessible from a porch, fire escape, or potential climbing point must be barricaded.

- Materials used for boarding-up include plywood, 2×4 braces, carriage bolt sets, and nails.

- Particle board, wafer board, Masonite, or similar materials are not suitable for boarding-up purposes.

- Securing Openings at Height

- Openings that are at least 10 feet from ground level and not accessible from porches, fire escapes, roofs, or other climbing points can be secured with nails in each brace and every 12 inches around the perimeter.

- Plywood should fit snugly against the exterior frame, aligning with the siding on wood frame buildings or the brick molding edge on brick buildings.

- Removal of the staff bead may be necessary to achieve a flush and tight fit.

- Posting NO TRESPASSING Signs

- After completing the board-up, the structure must be posted with a visible NO TRESPASSING sign to deter unauthorized entry.

Materials

- Plywood

- Exterior grade CDX plywood with a thickness of 1/2″ (4 ply) is used for boarding.

- Braces

- Construction-grade lumber measuring 2″ by 4″ by 8′ is used for braces.

- Carriage Bolts

- Carriage bolts with a coarse thread, 3/8″ in diameter and 12″ in length, are used.

- The bolts have rounded heads on the weather side.

- Nuts

- Construction-grade nuts with a diameter of 3/8″ (USS Standard) are used.

- Flat Washers

- Flat washers with a 1/2″ (USS Standard) inside diameter, large enough to bypass the wrench neck inside the carriage bolt head, are used.

- Additional 3/8″ flat washers are used for installation beneath the nut inside the building.

- Nails

- Galvanized or stainless steel ring-shank nails with a length of 1-5/8″ (6d) or comparable deck nails are used.

Installation

- Barriers Application

- Skilled carpenters are responsible for applying barriers inside and outside.

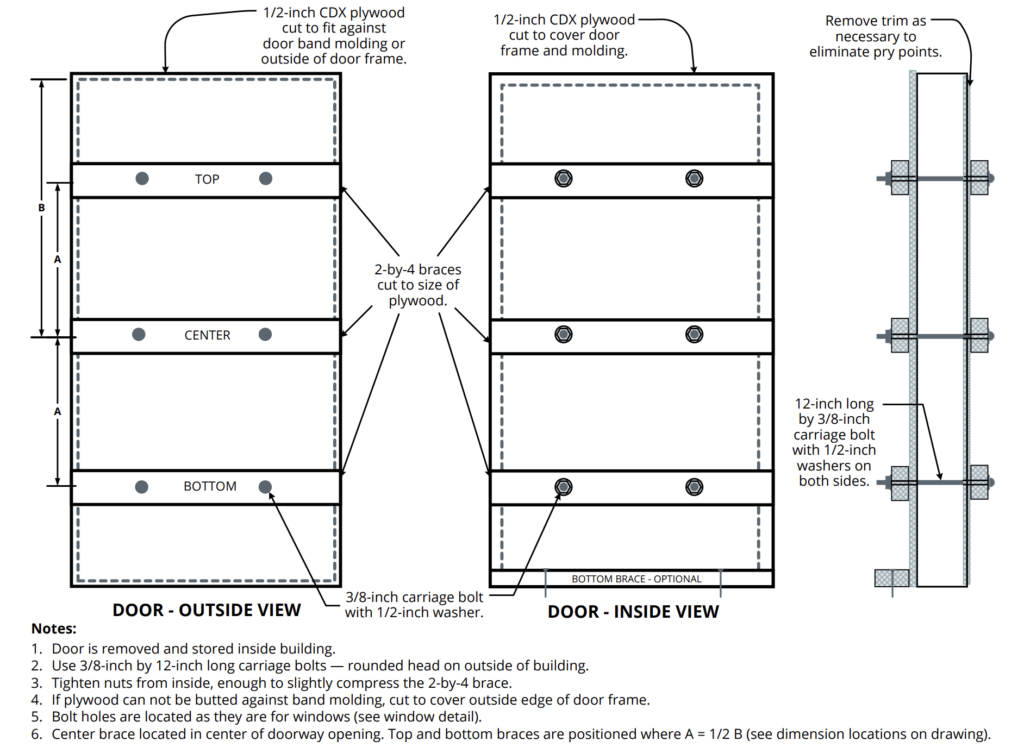

- Plywood is cut to fit over window and door openings, flush with the outside molding/trimmer stud.

- Care is taken to avoid any lift or pry points during application.

- Brace Placement

- For windows, braces are located horizontally at approximately 1/3 of the distance from the top and bottom of the window.

- Bolt holes are located 1/3 of the length of the brace from the outside edge of the window jams.

- For doors, one brace is placed in the center of the doorway, and the other two are positioned halfway from the center to the top and bottom of the doorway.

- Secure Assembly

- 3/8” holes are pre-drilled through all components before assembly.

- Carriage bolt assemblies are used to secure the 2×4 braces, with washers placed on both sides of the brace.

- Bolts are inserted from the exterior and tightened from the interior to compress the interior brace.

- Exterior Finish

- The exterior surfaces of barriers are painted or stained to match the structure’s color, minimizing their appearance.

- Alternative Method

- If through-bolt compression is impossible due to the opening’s size or condition, plywood is used, and it is secured with 3-inch-long deck or wood screws placed 4 inches apart around the opening’s circumference.

- Authorized Personnel Access

- Buildings requiring access by authorized personnel may have a single door secured using a solid core wood or steel door.

- This door should have no windows or openings and is securely locked using a padlock and hasp assembly bolted through the door.

I.C.C. I.P.M.C. APPENDIX A – BOARDING STANDARD

This standard outlines the minimum specifications for boarding a structure, offering a set of requirements to ensure consistent boarding quality. Please note that these provisions are not mandatory unless specifically referenced in the adopting ordinance of the authority having jurisdiction.

A101 – GENERAL

- Windows and doors must be boarded in an approved manner to prevent unauthorized entry.

- The boarded windows and doors should be painted to match the color of the existing structure.

A102 – MATERIALS

- Boarding sheet material must be a minimum of 1/2-inch-thick (12.7 mm) wood structural panels complying with the International Building Code.

- Boarding framing material should be a minimum nominal 2-inch by 4-inch (51 mm by 102 mm) solid sawn lumber complying with the International Building Code.

- Boarding fasteners should be a minimum of 1/4-inch-diameter (9.5 mm) carriage bolts of sufficient length to penetrate the assembly, along with washers and nuts complying with the International Building Code.

A103 – INSTALLATION

- The boarding installation should follow Figures A103.1(1) and A103.1(2) and Sections A103.2 through A103.5.

- Boarding sheet material should be cut to fit the door or window opening neatly or provide an equal overlap at the perimeter of the door or window.

- For windows, open the window to allow the carriage bolt to pass through, or remove and store the window sash.

- The 2-inch by 4-inch (51 mm by 102 mm) strong back framing material should be cut a minimum of 2 inches (51 mm) wider than the window opening.

- Place the strong back on the inside of the window opening, with a minimum distance of 6 inches (152 mm) above the bottom and below the top of the window opening.

- Framing and boarding should be pre-drilled, aligned, and secured.

A103.4 – DOOR WALLS

- The door opening should be framed with a minimum 2-inch by 4-inch (51 mm by 102 mm) framing material.

- Secure framing material at the entire perimeter and vertical members at a maximum of 24 inches (610 mm) on center.

- Blocking should also be secured at a maximum of 48 inches (1219 mm) on center vertically.

- Boarding sheet material should be secured with screws and nails alternating every 6 inches (152 mm) on center.

A103.5 – DOORS

- Doors should be secured using the same method as for windows or door openings.

- One door to the structure should be available for authorized entry, and it should be secured and locked in an approved manner.

A104 – REFERENCED STANDARD

- IBC-18 (International Building Code) is the referenced standard for A102.1, A102.2, and A102.3.

This detailed guide outlines the key requirements and standards specified in I.C.C. I.P.M.C. Appendix A for boarding structures. Remember that compliance with these standards is crucial to ensure the safety and security of structures.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.