Introduction

Polymeric cladding, widely known for its resilience and versatility, is an integral aspect of modern construction. This article provides a thorough examination of the building codes and safety regulations surrounding polymeric cladding, ensuring professionals are equipped with the necessary knowledge to apply best practices in construction and restoration.

Building Code Reference Guide

- IRC Chapter 7: Outlines general product and installation requirements for cladding.

- Product Requirements (IRC R703): Products must be certified and labeled in accordance with their respective ASTM standards.

- Installation Requirements (Cladding): Vinyl and polypropylene siding installation specifics.

- Soffit (IRC Section R704): Requirements for vinyl soffit panels installation.

- High-Density Development Considerations: Guidelines for using vinyl siding and polypropylene siding in proximity to property lines.

- Built-In Protection: Highlighting the benefits of polymeric cladding in fire safety.

- Residential Fires: Understanding the role of exterior cladding in residential fires.

- International Residential Code (IRC)

- Vinyl Siding: Must conform to ASTM D3679 — R703.11.

- Polypropylene Siding: Must adhere to ASTM D7254 — R703.14.

- Insulated Vinyl Siding: Should follow ASTM D7793 — R703.13.

- International Building Code (IBC)

- IBC Chapter 14: Details general product and installation requirements for cladding.

- Product Requirements (1403): Cladding products must conform to their respective ASTM standards.

- Installation Requirements: Specifications for installing vinyl siding and polypropylene siding.

- High-Density Development and Noncombustible Construction: Guidelines for using polymeric cladding in various construction scenarios.

- IBC Chapter 14: Details general product and installation requirements for cladding.

International Building Codes and Polymeric Cladding Highlights:

INTERNATIONAL ENERGY CONSERVATION CODE (IECC)

- Insulated sidings recognized as effective continuous insulation.

- Enhances wall’s overall R-Value for improved energy efficiency.

- R-Value/U-Factor requirements: Insulated sidings must meet IECC benchmarks.

- R-Value must be labeled on insulated siding packaging as per code N1101.10.1 (R303.1.1).

- Insulated siding R-Value can be integrated into IECC’s prescriptive R-Value computation.

INTERNATIONAL WILDLAND-URBAN INTERFACE CODE (IWUIC)

- Polymeric cladding approved for use under all IWUIC conditions with performance benchmarks.

- IWUIC Chapter 5 classifies developments by wildfire risk, setting material specifications.

- Three distinct risk categories influence Ignition Resistant (IR) wall construction criteria.

- IR1 and IR2 constructions: Polymeric cladding must be part of 1-hour E119-rated assembly with flame spread index ≤ 25.

- IR3 conditions have no specific wall construction or cladding type requirements.

Florida Building Codes on Polymeric Cladding: A Brief Overview

Florida Residential Code (Chapter 7)

- Product Requirements: All products must be certified and display labels proving their conformity to the established ASTM standard.

- Wind Loads: Cladding and soffit must meet the wind loads specified in the code (R301.9, R703.11.1, and R703.13.1).

- Installation Requirements: Vinyl and insulated vinyl siding should be installed 16″ on center using roofing nails, with certain variations permitted. Polypropylene siding needs to be installed over wood sheathing.

- High-Density Settings: Polypropylene siding used in high-density environments must have a certified E84 or UL723 flame spread test report.

Florida Building Code (Chapter 14)

- Product Requirements: Products need certification and labeled conformity to their set ASTM standard.

- Moisture Management: Vinyl siding and polypropylene siding are recognized as vented claddings, which can eliminate the need for vapor retarders due to their strong moisture management characteristics.

- Florida Energy Code: Insulated vinyl siding with a minimum R-2 rating can serve as continuous insulation for energy code compliance in Florida.

Understanding Polymeric Cladding Performance in High Wind Regions

- Design Pressure Rating: It reflects the highest wind application suitable for the cladding.

- Wind Speed Measurement: Standardized measurement but is an approximation based on various factors.

- Standard Wind Load Design Pressure Rating: Provides a more accurate prediction of a product’s performance in varied conditions.

- Coastal Installation Tips: Current codes regulate coastal areas with stringent performance requirements for cladding. Polymeric claddings are suitable for such conditions due to their resilience to extreme coastal environments.

- High Wind Regions: Vinyl siding and insulated vinyl siding products intended for use in high-wind regions generally have reinforced nail hems. Polypropylene siding in these regions typically needs installation 8″ to 10″ on center based on the manufacturer’s instructions.

Installing Polymeric Cladding in Coastal Areas

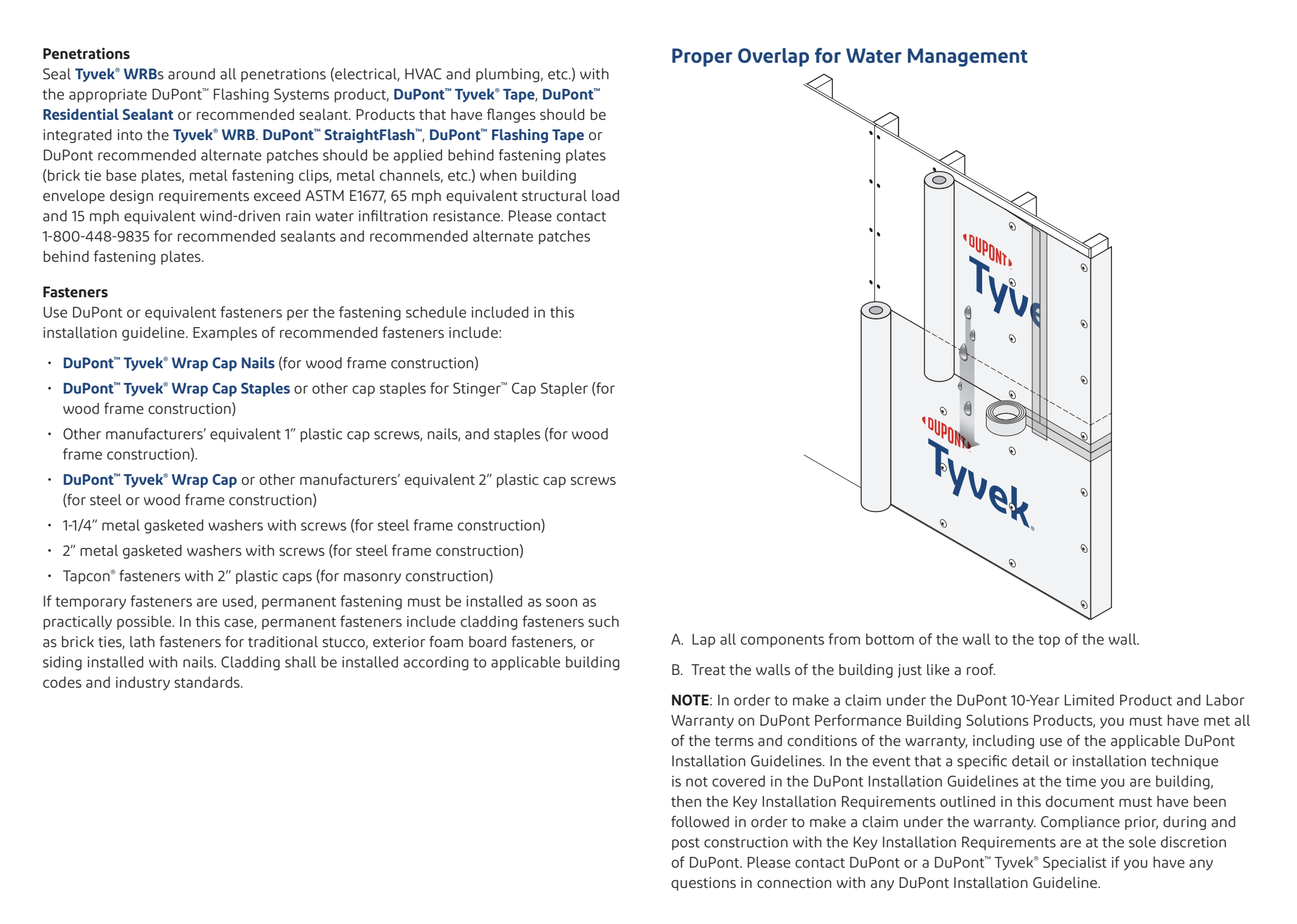

- Siding Installation Tips: Starter strips are crucial in regular wall applications. Each type of siding has a unique starter strip, and they shouldn’t be used interchangeably.

- Importance of Proper Starter Strip: Using an incorrect starter strip or substituting with J-channel or other trims can result in product failure.

Florida Building Codes on Polymeric Cladding: A Brief Overview

Florida Residential Code (Chapter 7)

- Product Requirements: All products must be certified and display labels proving their conformity to the established ASTM standard.

- Wind Loads: Cladding and soffit must meet the wind loads specified in the code (R301.9, R703.11.1, and R703.13.1).

- Installation Requirements: Vinyl and insulated vinyl siding should be installed 16″ on center using roofing nails, with certain variations permitted. Polypropylene siding needs to be installed over wood sheathing.

- High-Density Settings: Polypropylene siding used in high-density environments must have a certified E84 or UL723 flame spread test report.

Florida Building Code (Chapter 14)

- Product Requirements: Products need certification and labeled conformity to their set ASTM standard.

- Moisture Management: Vinyl siding and polypropylene siding are recognized as vented claddings, which can eliminate the need for vapor retarders due to their strong moisture management characteristics.

- Florida Energy Code: Insulated vinyl siding with a minimum R-2 rating can serve as continuous insulation for energy code compliance in Florida.

Understanding Polymeric Cladding Performance in High Wind Regions

- Design Pressure Rating: It reflects the highest wind application suitable for the cladding.

- Wind Speed Measurement: Standardized measurement but is an approximation based on various factors.

- Standard Wind Load Design Pressure Rating: Provides a more accurate prediction of a product’s performance in varied conditions.

- Coastal Installation Tips: Current codes regulate coastal areas with stringent performance requirements for cladding. Polymeric claddings are suitable for such conditions due to their resilience to extreme coastal environments.

- High Wind Regions: Vinyl siding and insulated vinyl siding products intended for use in high-wind regions generally have reinforced nail hems. Polypropylene siding in these regions typically needs installation 8″ to 10″ on center based on the manufacturer’s instructions.

Installing Polymeric Cladding in Coastal Areas

- Siding Installation Tips: Starter strips are crucial in regular wall applications. Each type of siding has a unique starter strip, and they shouldn’t be used interchangeably.

- Importance of Proper Starter Strip: Using an incorrect starter strip or substituting with J-channel or other trims can result in product failure.

International & National Building Code Quick Reference Chart for Polymeric Cladding

INTERNATIONAL CODES

| Vinyl Siding | Insulated Vinyl Siding | Polypropylene Siding |

|---|---|---|

| International Residential Code (IRC) |

- ASTM D3679

- Installed 16″ on center using roofing nails

- Vinyl soffit must meet specific design pressure in high-wind areas

- No limitations for high-density applications

- ASTM D7793

- Installed 16″ on center using roofing nails

- Not specifically addressed in the International Building Code (IBC)

- ASTM D7254

- Installation as per manufacturer’s instructions

- Must be installed over wood sheathing

- Limited use in high-density applications unless certified E84 flame spread test report is available

International Building Code (IBC)

- ASTM D3679

- Installed 16″ on center using roofing nails

- Allowed on buildings with wind speed < 100 mph & height < 40 feet

- Refer to code compliance reports

- Not specifically addressed

- ASTM D7254

- Installed as per manufacturer’s instructions

- Must be installed over wood sheathing

- Allowed on buildings with wind speed < 100 mph & height < 40 feet

International Energy Conservation Code (IECC)

- Can be used as continuous insulation to meet R-Value/U-factor requirements

International Wildland-Urban Interface Code

FLORIDA BUILDING CODES

| Vinyl Siding | Insulated Vinyl Siding | Polypropylene Siding |

|---|---|---|

| Florida Residential Code |

- ASTM D3679

- Installed 16″ on center using roofing nails

- Vinyl soffit must meet specific design pressure in high-wind areas

- No limitations for high-density applications

- ASTM D7793

- Installed 16″ on center using roofing nails

- ASTM D7254

- Installation as per manufacturer’s instructions

- Must be installed over wood sheathing

- Limited use in high-density applications unless certified E84 flame spread test report is available

Florida Building Code

- ASTM D3679

- Installed 16″ on center using roofing nails

- Allowed on buildings with wind speed < 100 mph & height < 40 feet

- Refer to code compliance reports

- Not specifically addressed

- ASTM D7254

- Installed as per manufacturer’s instructions

- Must be installed over wood sheathing

- Allowed on buildings with wind speed < 100 mph & height < 40 feet

Florida Energy Code

- Insulated vinyl siding with a minimum R-2 can be used for energy code compliance

NATIONAL BUILDING CODE OF CANADA (NBCC)

| Vinyl Siding | Insulated Vinyl Siding | Polypropylene Siding |

|---|

- ASTM D3679

- Flame spread rating when required by code

- Fasteners installed in center of nail slot

- ASTM D7793

- Flame spread rating when required by code

- ASTM D7254

- Flame spread rating when required by code

- Fasteners installed in the center of the nail slot

Summary

Polymeric cladding is a reliable and durable solution for exterior protection and aesthetics. Adhering to building codes and understanding safety standards is crucial for ensuring the longevity and performance of the cladding. By following the guidelines outlined in the IRC and IBC, professionals can ensure that their projects meet or exceed industry standards for safety and quality. As the use of polymeric cladding continues to grow, it’s essential to stay informed about the latest regulations and best practices in the industry.

For more personalized guidance, consult with engineers and local building codes specific to your location. For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field