The issue of water-soluble residue—commonly referred to as “tobacco juicing” due to its distinct brownish hue—on asphalt roofing products has been a subject of concern for homeowners, contractors, and industry professionals alike. While this phenomenon is often associated with asphalt roofing materials such as shingles, base and cap sheets, and roof coatings, it’s important to note that the root cause may not solely be the roofing material itself.

Environmental Factors

Recent studies have indicated that environmental elements like air pollution, nighttime dew conditions, and an extended absence of rainfall contribute significantly to the formation of tobacco juicing. Air pollutants can accumulate on the roofing surface, combine with dew, and then run off onto lower roofing areas, fascia, and other finishes.

Implications for Different Roof Slopes

Steep Slope Applications

On steep slopes, typically seen in asphalt shingled roofs, tobacco juicing can drip off and stain adjacent components. However, this residue usually does not affect the roof’s overall performance and is primarily an aesthetic concern.

Low Slope Applications

For roofs with a low slope, the accumulation of this residue can interfere with the proper adhesion of coatings. It is crucial to follow guidelines set forth by the Roof Coatings Manufacturers Association (RCMA) and the Asphalt Roofing Manufacturers Association (ARMA) for preparing the roof for coating applications.

Recommendations

To mitigate the aesthetic impact of tobacco juicing, consider the following:

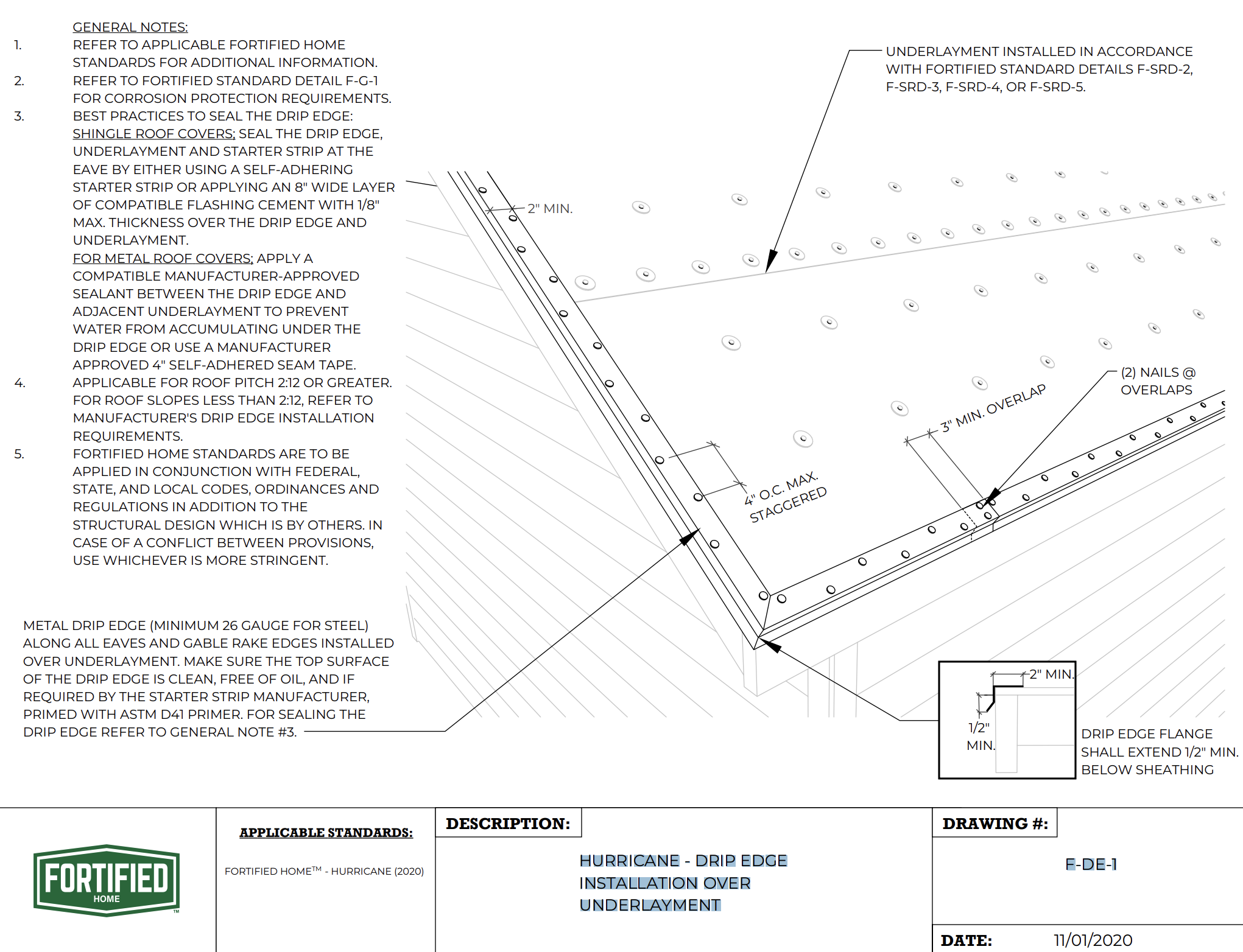

- Edge Metal Installation: Utilize edge metal with a drip lip on parapet walls to ensure the runoff falls away from the building.

- Regular Cleaning: Hose down the roof periodically, especially during long, dry spells in the first summer after installation. This is not advised if safety measures like fall protection are not in place.

- Coating Applications: For low slope roofs, applying aluminum or acrylic coatings can minimize the aesthetic effects of tobacco juicing. Follow manufacturer guidelines for curing times before applying the coating.

- Manufacturer Consultation: Always consult the specific material manufacturer for tailored recommendations.

Final Thoughts

Tobacco juicing may not be completely avoidable due to environmental factors, but understanding its causes and following established guidelines can certainly help in minimizing its impact. It’s crucial for specifiers, contractors, and homeowners to take the necessary steps to address this issue effectively.

For more information or assistance, our team of experts at Allied Emergency Services, INC is here to provide consultation and restoration services tailored to your needs. Feel free to reach out to us for immediate service.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field.