Introduction

Structural sheathing in exterior walls is a critical component for safeguarding homes against the forces of high-wind events like hurricanes and tornadoes. In this blog, we delve into best practices for installing plywood or OSB (Oriented Strand Board) structural sheathing, with a particular focus on high-wind and hurricane-prone regions.

Importance of Structural Sheathing

During extreme wind events, a building’s wall system can experience structural failures and water damage. Gaps or unsealed joints in the wall’s structural sheathing can allow rainwater to infiltrate, leading to significant damage. A fully sheathed wall, properly anchored, acts as a robust barrier against such events. Shear walls, made up of braced panels, are designed to counteract lateral loads, enhancing the building’s resilience against wind forces.

Regulatory Landscape

The International Residential Code (IRC) sets forth requirements for exterior components to withstand design wind pressures. For homes in high-wind or hurricane-prone regions, enhanced attachment standards are often mandated. Always consult local building departments for region-specific requirements.

Key Considerations for Installation

Material Selection

- Plywood/OSB Thickness: The minimum thickness for structural sheathing panels is 7/16”, except for gable end walls where 3/8” is permissible.

Fastening and Bracing

- Fastening Schedule: Opt for a fastening schedule that is consistent with IRC’s Section R602.

- Braced Walls: Determine the amount and location of braced walls (shear walls) for each story.

Special Programs

The Insurance Institute for Business and Home Safety® (IBHS) offers the Fortified Home program, which provides additional guidance and standards for homes in high-risk areas. The program focuses on various components of a home, from the roof to the walls and structural attachments.

Installation Steps

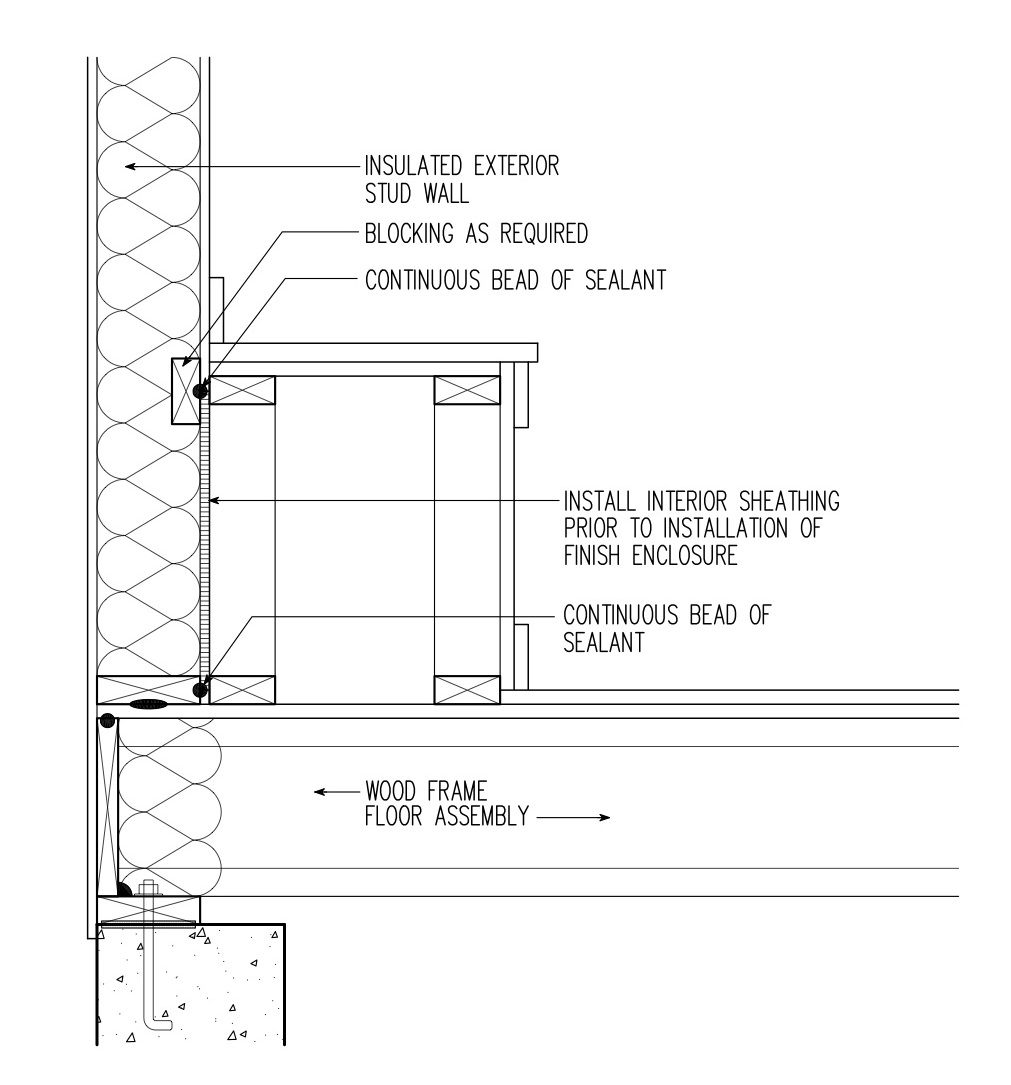

- Full Sheathing: Exterior walls must be fully sheathed with a minimum 7/16-in. wood structural panels.

- Gable End Walls: Use a minimum of 3/8-in. structural sheathing panels. These walls must be securely tied to the structure.

- Anchoring: Employ hurricane clips or framing anchors on all rafter-to-wall connections.

- Nailing: Increase nailing to 8d ring shank or 10d nails with specific spacing requirements.

- Water Resistive Barrier (WRB): Install a WRB over the structural sheathing to protect against water infiltration.

Compliance: Adhering to Building Codes and Regulations

International Residential Code (IRC) Guidelines

- Wood Structural Panels: According to IRC Sections R602.1.8, structural panels should conform to DOC PS 1 or DOC PS 2 standards. They must be identified for grade, bond classification, and performance category.

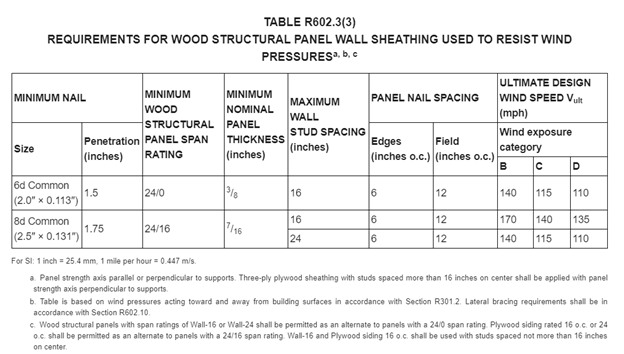

- Design and Construction: IRC Section R602.3 and Table R602.3(3) lay out specific requirements for wood structural panel wall sheathing used to resist wind pressures.

- Braced Wall Requirements: IRC Sections R602.3.5, R602.10.1.3, R602.10.2.1, and R602.10.5 detail the uplift load path, spacing, and minimum length of braced wall panels.

Retrofitting Standards

- For retrofitting projects, IRC Sections from 2009, 2012, 2015, 2018, and 2021 apply. Section R102.7.1 states that any alterations or repairs must comply with the current code without necessitating updates to unaltered existing building sections.

- Appendix J: This section governs the repair, renovation, and alteration of existing buildings, aiming to ensure their continued safe use.

IBHS Gable End Wall Retrofit Guidelines for Existing Homes

IBHS (Insurance Institute for Business and Home Safety) offers a High Wind Standard for retrofitting gable end walls in high-wind areas. These align with the International Existing Building Code (ICC 2018).

Key Points:

- Strengthen Vertical Framing: Utilize retrofit studs.

- Horizontal Bracing: Add top and bottom braces for lateral load support.

- Metal Connections: Use metal straps for connecting braces and retrofit studs, and metal bracket connectors for bottom gable ends.

- Sheathing: Minimum of 3/8-in. OSB or plywood required.

Minimum Requirements:

- Ceiling: At least 1/2-in. drywall or 3/8-in. plywood.

- Roof: Minimum 3/8-in. plywood or OSB.

- Gable Ends: Must have 3/8-in. structural sheathing.

Special Cases:

For gable ends taller than 16 ft, irregularly shaped, or in rooms with vaulted ceilings, consult a licensed professional engineer for a custom bracing system.

Conclusion

Whether you’re involved in new construction or a retrofit project, the selection and installation of structural sheathing are crucial steps for ensuring your building can withstand the forces of extreme weather. Always refer to local and international building codes and consider participating in special programs like IBHS’s Fortified Home for enhanced resilience.

For more personalized guidance, consult with engineers and local building codes specific to your location. For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field