Introduction

In the complex anatomy of a home, the building enclosure—comprising the walls, floors, and ceiling—serves as the protective shell. Within this shell lie critical components like insulation (thermal envelope) and air barriers. These elements play a crucial role in maintaining the home’s energy efficiency and indoor air quality. This blog post aims to shed light on the concept of continuous air barriers in exterior walls, why they are essential, and how to install them effectively.

What is a Continuous Air Barrier?

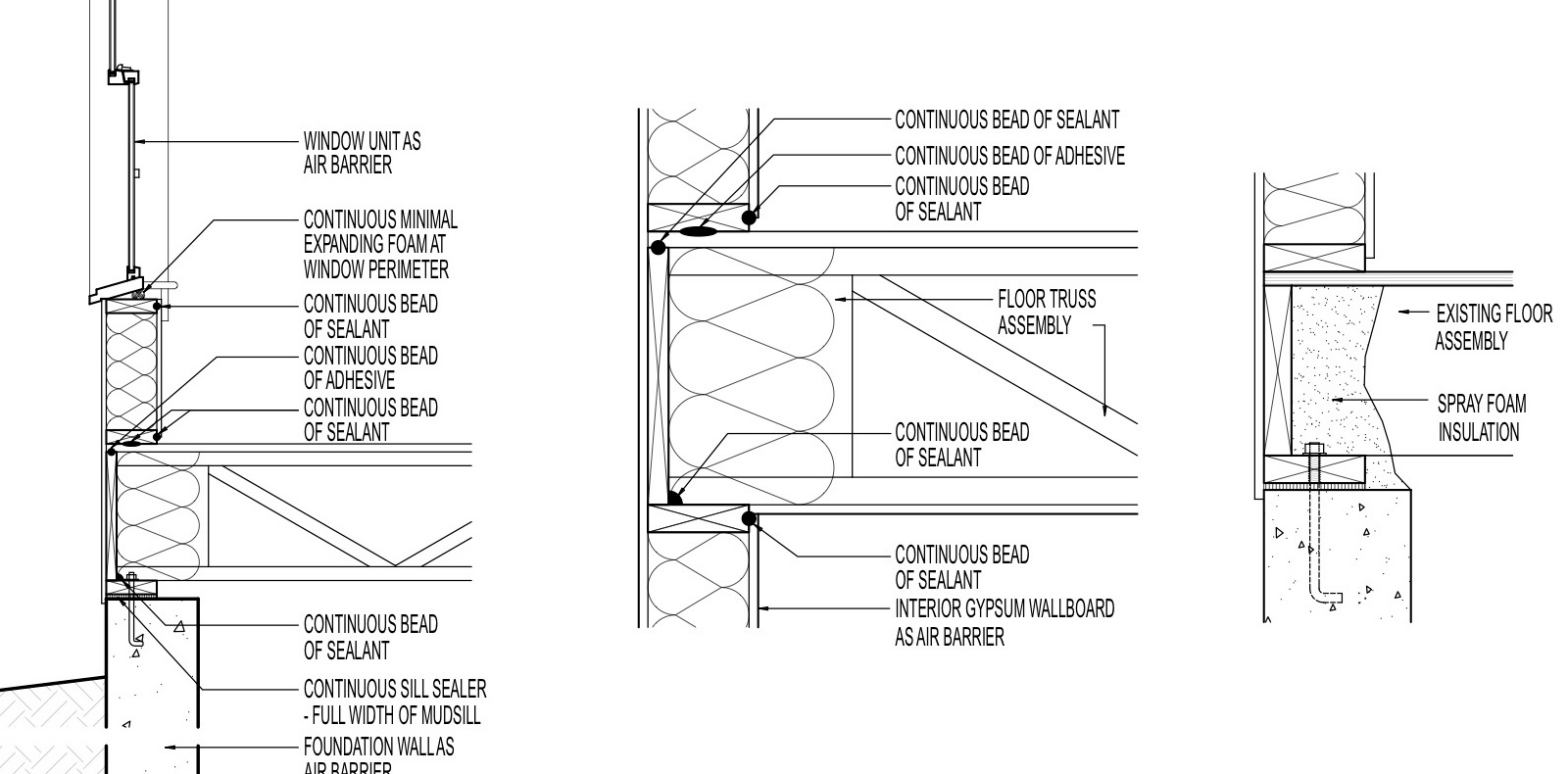

A continuous air barrier is a layer or layers that prevent the unauthorized entry of external air and the escape of indoor air. It is mandatory by building codes such as the 2009, 2012, and 2015 IRC for the thermal layer of insulation to be in full contact with the home’s continuous air barrier. Materials like drywall, OSB, or rigid foam insulation can serve as air barriers.

Characteristics of Effective Air Barriers:

- Durability: The material should be able to withstand both positive and negative pressures without damage.

- Sealing: All seams, edges, and holes should be sealed using long-lasting air-sealing materials like caulk or spray foam.

- Alignment: It should align with the exterior vertical surface of the insulation in walls across all climate zones.

Why Do You Need a Continuous Air Barrier?

- Energy Efficiency: Properly installed air barriers can significantly reduce energy consumption for heating and cooling.

- Indoor Air Quality: They help in preventing the infiltration of pollutants and allergens from outside.

- Moisture Control: By blocking unauthorized air flow, air barriers also prevent moisture issues that could lead to mold growth and structural damage.

How to Install a Continuous Air Barrier

Planning:

- Determine the Location: Consult ENERGY STAR Rater Field Checklist to determine the appropriate location of the air barrier based on the home’s climate zone.

- Specify on Plans: Clearly mark the components that will form the air barrier on the house plans.

Installation:

- Material Selection: Choose a durable material like rigid foam insulation for the air barrier.

- Sealing: Use appropriate sealing materials to seal all seams, gaps, and holes. This includes caulking seams in sheathing and using spray foam around wiring and piping.

- Support: Make sure that the material is adequately supported to resist pressures without displacement.

Post-Installation:

- Inspection: After installation, inspect to ensure that the air barrier is continuous and free of any gaps or holes.

- Alignment: The insulation should be in full alignment with the air barrier to meet RESNET Grade I Insulation Installation Standards.

Scope of Installation

The scope of installing a continuous air barrier is to envelop the entire thermal shell of a home. This includes not just the walls but also the floors and ceilings. The materials used for the air barrier should be clearly identified in the house plans across all these components.

Types of Air Barrier Materials:

- Rigid Materials: Foam board insulation, drywall, plywood, or OSB.

- Flexible Materials: House wrap, sealed at all seams and edges and supported using approved fasteners. Avoid materials that tear easily like kraft paper.

- Fluid-Applied Membranes: Liquid membranes applied over the sheathing.

- Spray Foam: Minimum thickness of 5.5 inches for open-cell and 1.5 inches for closed-cell spray foam insulation.

Note: All seams, gaps, and holes should be meticulously sealed.

Ensuring Success

Verification Steps:

- Visual Inspection: Confirm the presence of a continuous air barrier and ensure all seams, gaps, and holes are sealed.

- Blower Door Test: Verify whole-house air leakage.

- Insulation Levels: Inspect that all insulation levels meet or exceed the 2009 IECC levels and achieve Grade I installation as per RESNET standards.

Typical R-values for Common Insulation

To further ensure the effectiveness of your thermal envelope, you can refer to summarized tables for R-values and vapor retarder classifications for each type of insulation.

Compliance

Key Compliances to Consider:

Energy Star Guidelines

- Fully-Aligned Air Barriers in all insulated locations.

- Exterior vertical surface in all climate zones.

- Interior vertical surface in Climate Zones 4-8.

DOE Zero Energy Ready Home

- Certified under ENERGY STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Program.

- Certified under EPA Indoor airPLUS.

- Whole house leakage must meet specified infiltration limits according to climate zones.

IECC and IRC Guidelines (2009-2021)

- Meet or exceed the minimum insulation requirements for ceilings, walls, floors, and foundations.

- A continuous air barrier is installed in the building envelope.

- Air-permeable insulation is not used as a sealing material.

- Testing for air leakage to meet specified rates.

- Table N1102.4.2 – Air Barrier and Insulation Inspection Component Criteria

- Table N1102.4.1.1 – Air Barrier and Insulation Installation

- N1102.4.1.1 – Specifies requirements for a continuous air barrier in the building envelope, including rim joists and exposed edges of insulation. It also mandates that breaks or joints in the air barrier be sealed.

- Section R102.7.1 – Stipulates that additions, alterations, renovations, or repairs must conform to the provisions of the current code, without requiring the unaltered portions of the existing building to comply.

- Appendix J – Regulates the repair, renovation, alteration, and reconstruction of existing buildings, intending to encourage their continued safe use.

Retrofit Guidelines

All additions, alterations, renovations, or repairs must conform to the provisions of the current code.

ASTM E1677-11

Comply with the standard specification for Air Barrier Material or System for framed walls in low-rise buildings.

Code Requirements:

Different versions of the IECC and IRC lay out various requirements for air barriers. Compliance with the latest versions ensures the highest level of air-tightness and energy efficiency. The building should be tested for air leakage and should meet stringent standards laid out in the codes.

Conclusion

The installation of a continuous air barrier is not just a code requirement but a best practice that pays dividends in energy savings and improved indoor air quality. By following the guidelines mentioned above, homeowners and contractors can ensure that their building envelope is as energy-efficient as possible.

For more personalized guidance, consult with engineers and local building codes specific to your location. For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field

![How Much Does a New Roof Cost in Illinois? [2024 Pricing Guide]](https://www.news.alliedemergencyservices.com/wp-content/uploads/2024/05/DALL·E-2024-05-07-15.14.25-A-professional-roofing-contractor-inspecting-a-roof-in-the-foreground-of-a-picturesque-suburban-neighborhood-in-Illinois.-The-contractor-is-wearing-a--150x150.webp)