Welcome to Allied’s latest blog where we dive into the nuances of Oriented Strand Board (OSB) using the authoritative guide from APA – The Engineered Wood Association’s TT-133. This document is a goldmine for construction professionals seeking to optimize the use of OSB in their projects.

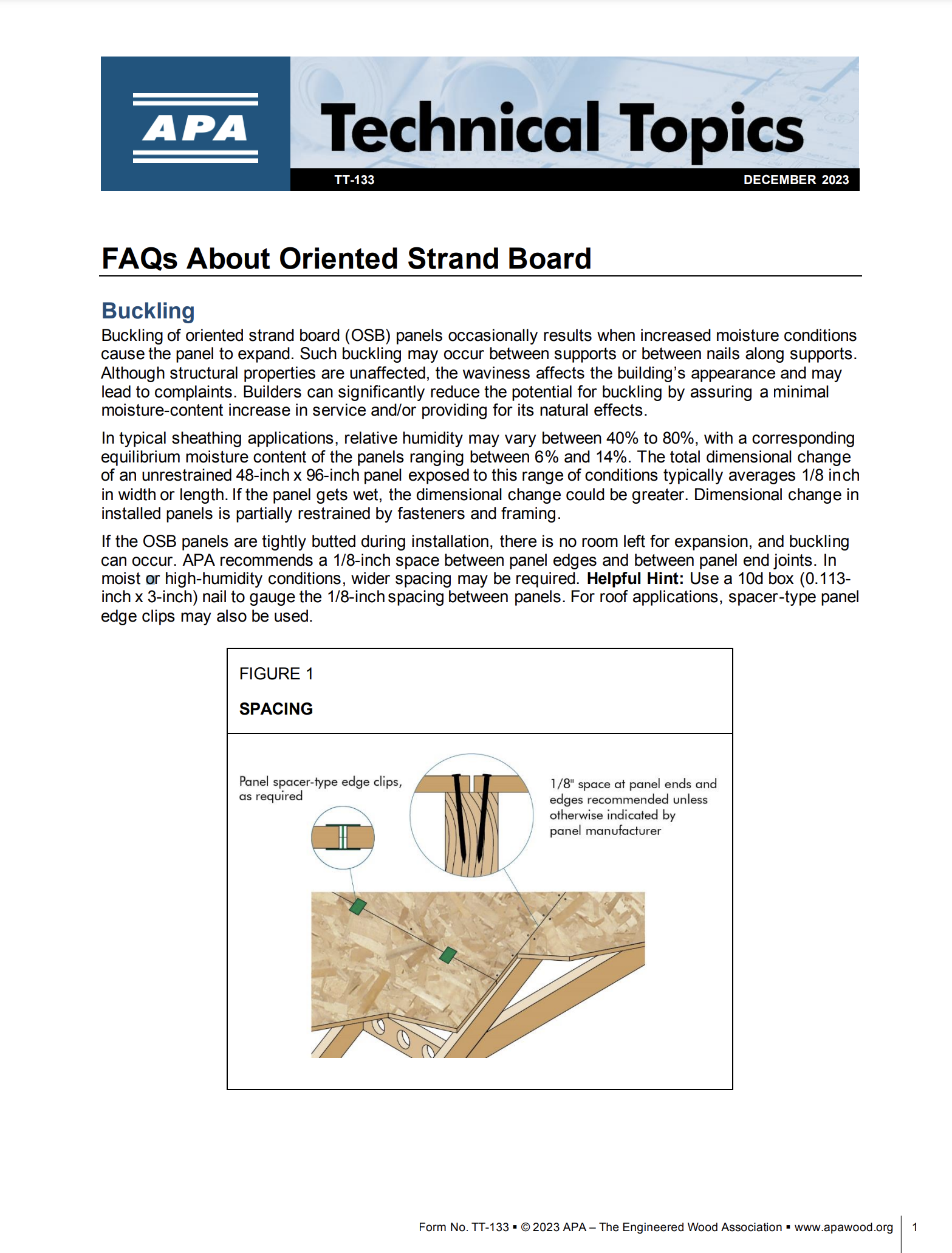

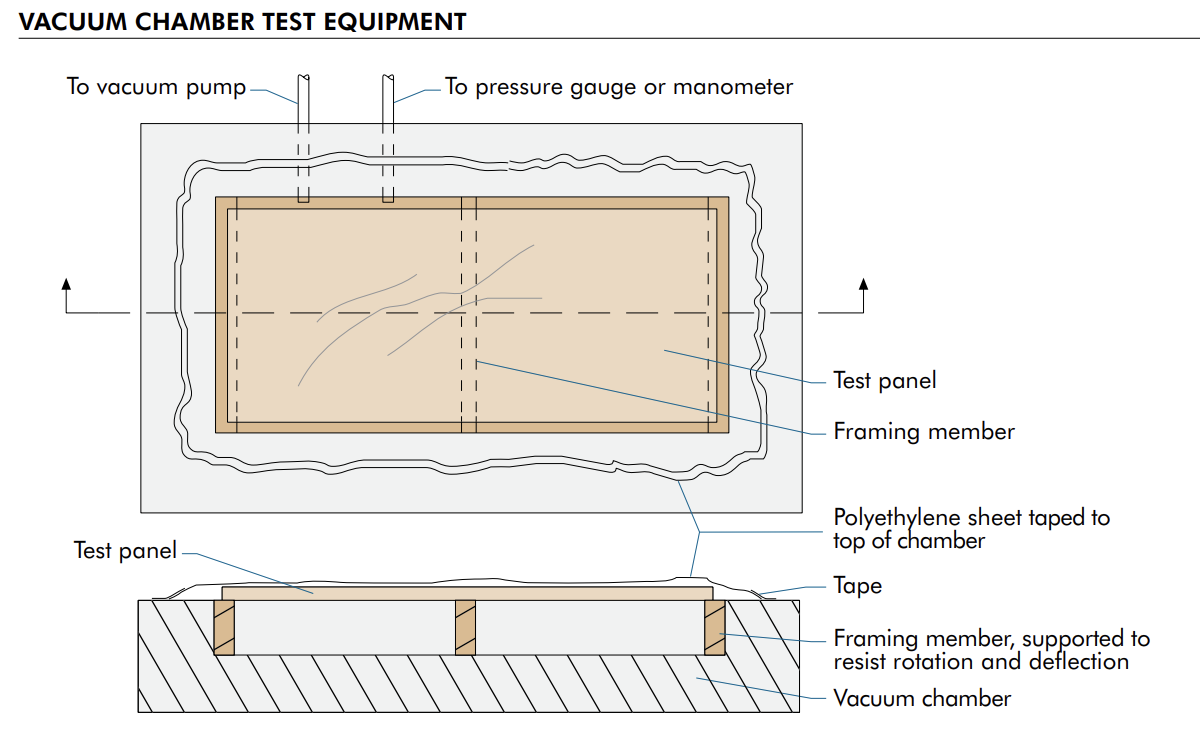

- Buckling: Buckling in OSB can occur due to increased moisture causing expansion. It’s recommended to leave a 1/8-inch space between panels for expansion, especially in moist conditions.

- Typical Fastener Recommendations: For securing OSB, use a minimum fastening schedule of nails at 6 inches on center at panel edges and 12 inches at intermediate supports.

- Surface Flaking: Exposure to moisture can cause roughness and flaking on OSB surfaces, but this doesn’t affect the structural capacity once dry.

- Thickness Swelling and Edge Swelling: Prolonged moisture exposure can cause irreversible thickness swelling, especially near edges, but it doesn’t usually affect structural capacity.

- Thickness Variances: OSB is produced to meet specific thickness tolerances as per U.S. standards, with variances within a 1/32-inch tolerance for most thicknesses.

- Discoloration: Changes in color can occur due to UV light and moisture, affecting only the surface appearance, not the performance.

- Linear Expansion: OSB can expand with moisture changes, typically averaging 1/8 inch in width or length for a standard panel.

- Sized for Spacing: Panels are often made slightly smaller than nominal sizes to allow for proper spacing and moisture-related growth.

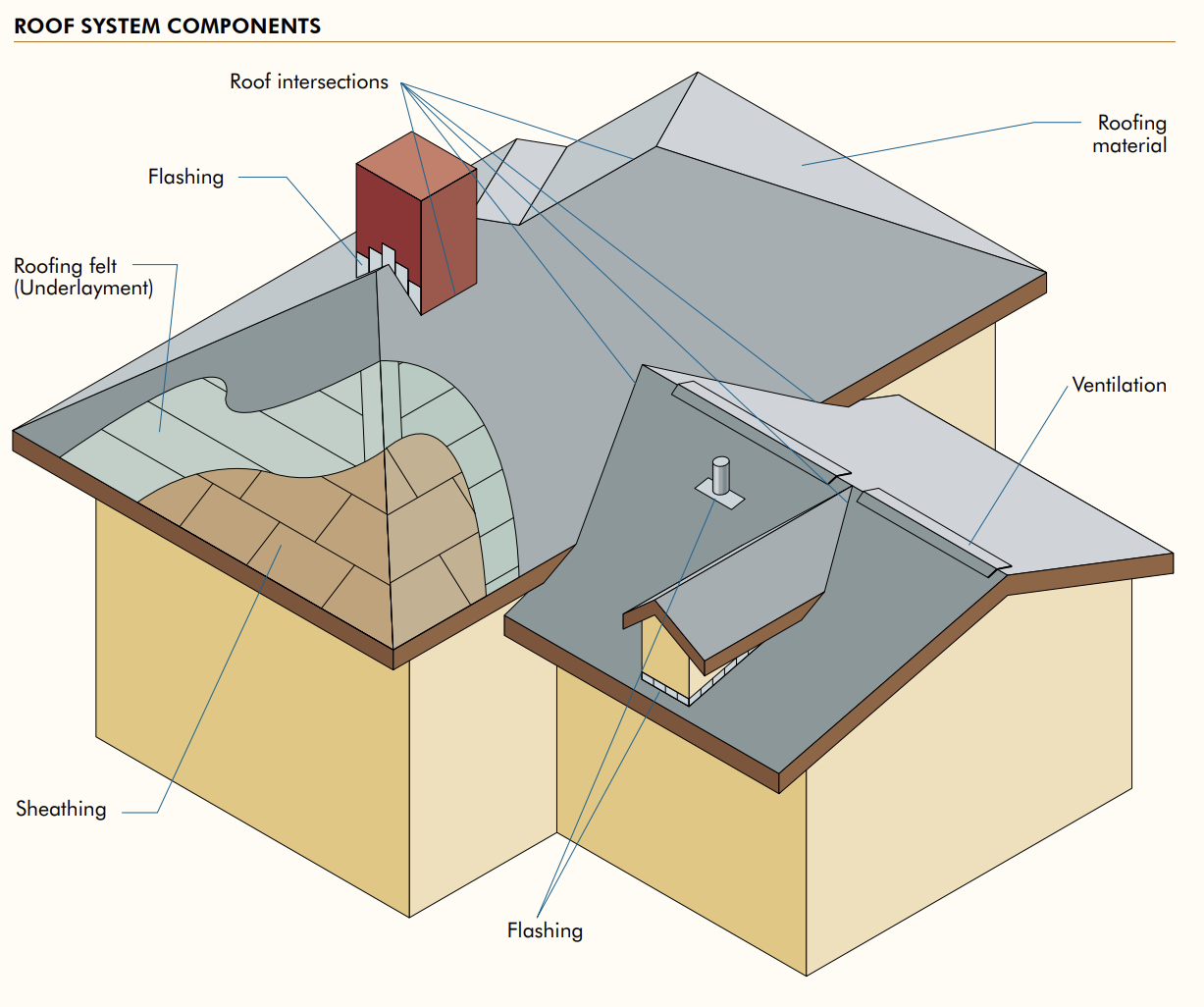

- Limited Exposure: OSB panels are made with moisture-resistant adhesives and are classified as Exterior or Exposure 1, depending on their intended use and moisture resistance.

- Conditioning & Acclimation: Conditioning OSB to the building environment before installation can reduce risks like buckling.

- Mold, Mildew and Moisture Management: OSB can be prone to mold and mildew in high moisture conditions, requiring proper moisture management and cleaning procedures.

APA’s TT-133 document is an indispensable resource for anyone working with OSB in construction. By understanding and applying these insights, construction professionals can ensure the longevity and effectiveness of their OSB installations.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field