Introduction

In the construction industry, the structural performance of building materials is of paramount importance to ensure the safety and reliability of structures. Structural Plywood is a commonly used engineered wood product in construction, known for its versatility and strength. To evaluate the structural performance of Structural Plywood, various tests are conducted, including tests for performance under concentrated static and impact loads, as well as tests for performance under uniform loads.

Tests for Performance Under Concentrated Static and Impact Loads

6.2.1 General

The testing procedures for Structural Plywood’s performance under concentrated static and impact loads are conducted following the general provisions of ASTM E661, with specific modifications outlined in this section.

6.2.1.2 Specimen Preparation

Test specimens are prepared according to ASTM E661 and Table 7, taking into consideration the intended end use/span rating. Specimens are conditioned to dry, wet, or wet/redry conditions as required. The moisture content is closely monitored to ensure compliance with manufacturer specifications.

6.2.1.3 Test Procedure

- Concentrated Static: ASTM E661 procedures are followed, with the test frame constructed using lumber with nails or steel fasteners simulating nails. The loading rate is controlled to yield failure within a specified time frame.

- Concentrated Impact: ASTM E661 Method A procedures are followed with modifications for different span ratings. The test frame is constructed using lumber or steel, and the weight of the shot bag varies based on span ratings.

Test for Performance Under Uniform Loads

6.2.2 General

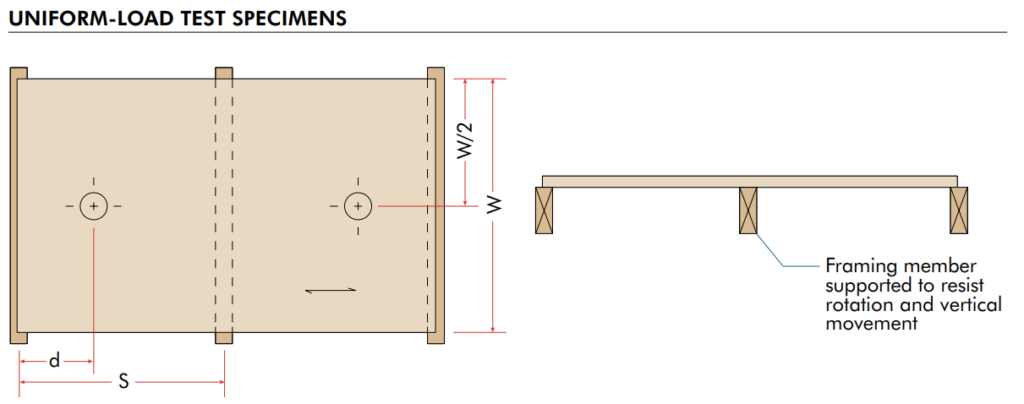

This method assesses the performance of structural-use Structural Plywood under uniform loads such as snow, wind, and occupancy loads. The uniform load is applied through atmospheric pressure in a vacuum chamber, with the specimen mounted on fully-supported framing members.

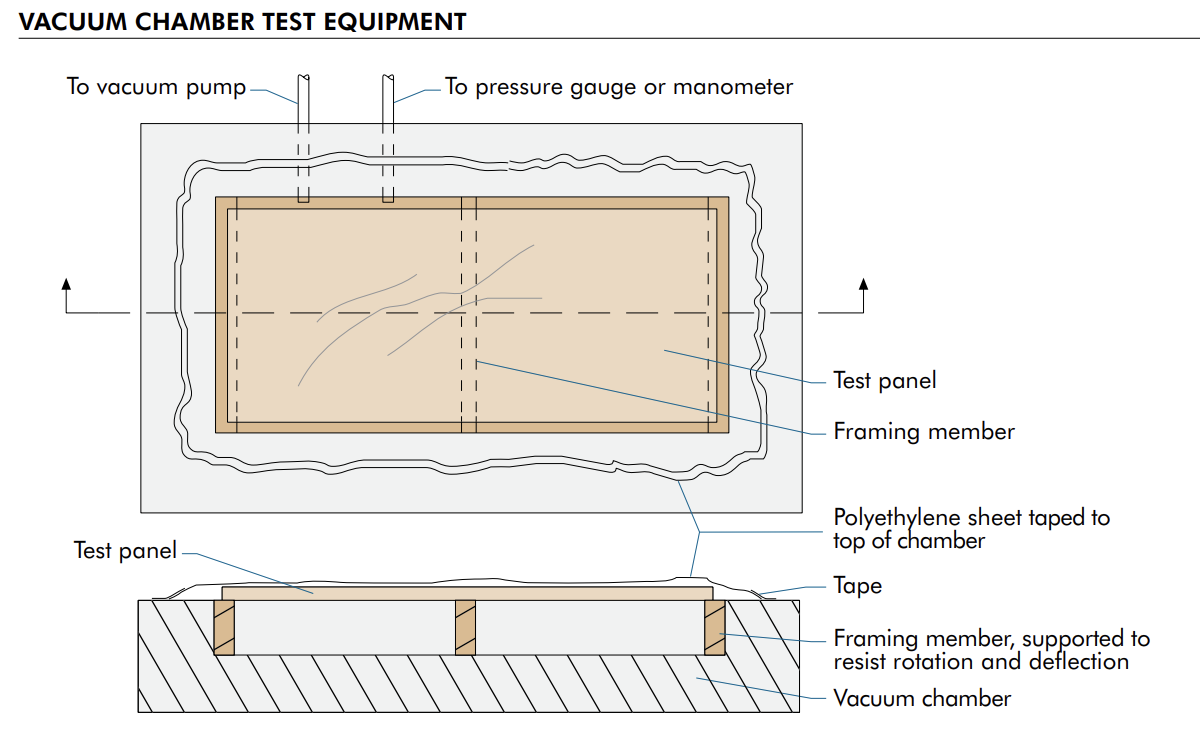

6.2.2.2 Equipment

- Vacuum Chamber: The vacuum chamber consists of a sealed box with the Structural Plywood panel forming the top. A polyethylene sheet seals the top surface of the chamber. The chamber must be strong and rigid to resist applied loads.

- Joist Supports: Framing members are spaced according to the intended span rating and supported to prevent deflection or rotation.

- Deflection Gages: Gages are used to measure deflection accurately.

6.2.2.3 Specimen Preparation

Test specimens are selected to be representative of the product. Length, width, and thickness are specified, and conditioning is carried out as per Table 8 and intended end use/span rating requirements.

6.2.2.4 Test Procedure

The specimen is mounted on framing members in the vacuum chamber, and the top is sealed. The deflection gages are positioned to measure deflection at specific points. The panel is loaded at a uniform rate, and deflections are recorded until maximum load or desired proof load is achieved.

In summary, these tests provide valuable insights into the structural performance of Structural Plywood, ensuring its suitability for various construction applications.

For immediate service or consultation, you may contact us at Allied Emergency Services, INC.

Contact Information:

- Phone: 1-800-792-0212

- Email: Info@AlliedEmergencyServices.com

- Location: Serving Illinois, Wisconsin, and Indiana with a focus on the greater Chicago area.

If you require immediate assistance or have specific questions, our human support is readily available to help you.

Disclaimer: This article is intended for informational purposes only. For professional advice, consult experts in the field